Your basket is currently empty!

| 1.20 | |

| 0.97 | |

| 13.6 kg | |

| Cast iron, corrosion-protected | |

| Heat-treated steel | |

| Mineral lubricating oil | |

| 3000 | |

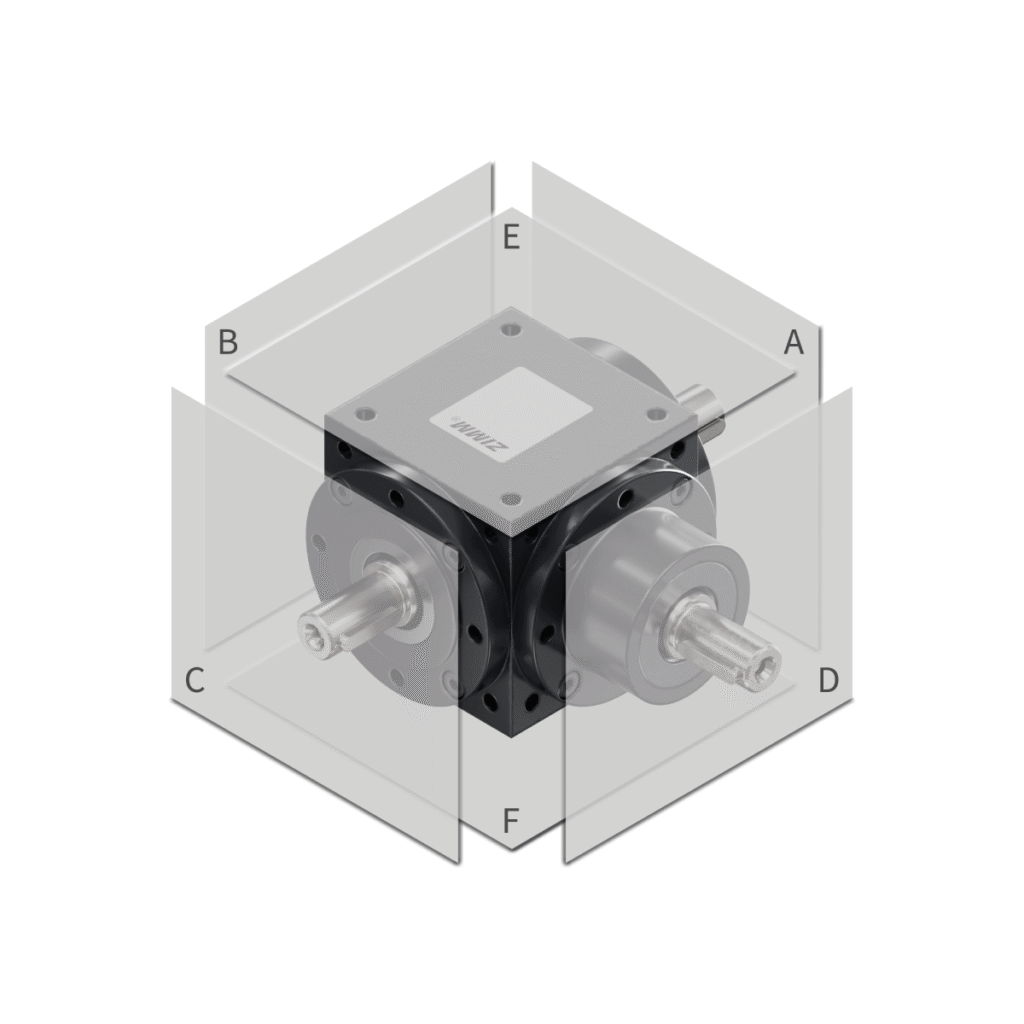

| 1700 rpm (shaft D; x:1) 1700 rpm (shaft A, C; 1:1) 3000 rpm (shaft A,C; 2:1 / 3:1) | |

| NBR3 | |

| Form A4 | |

| DIN 6885-1 Form A |

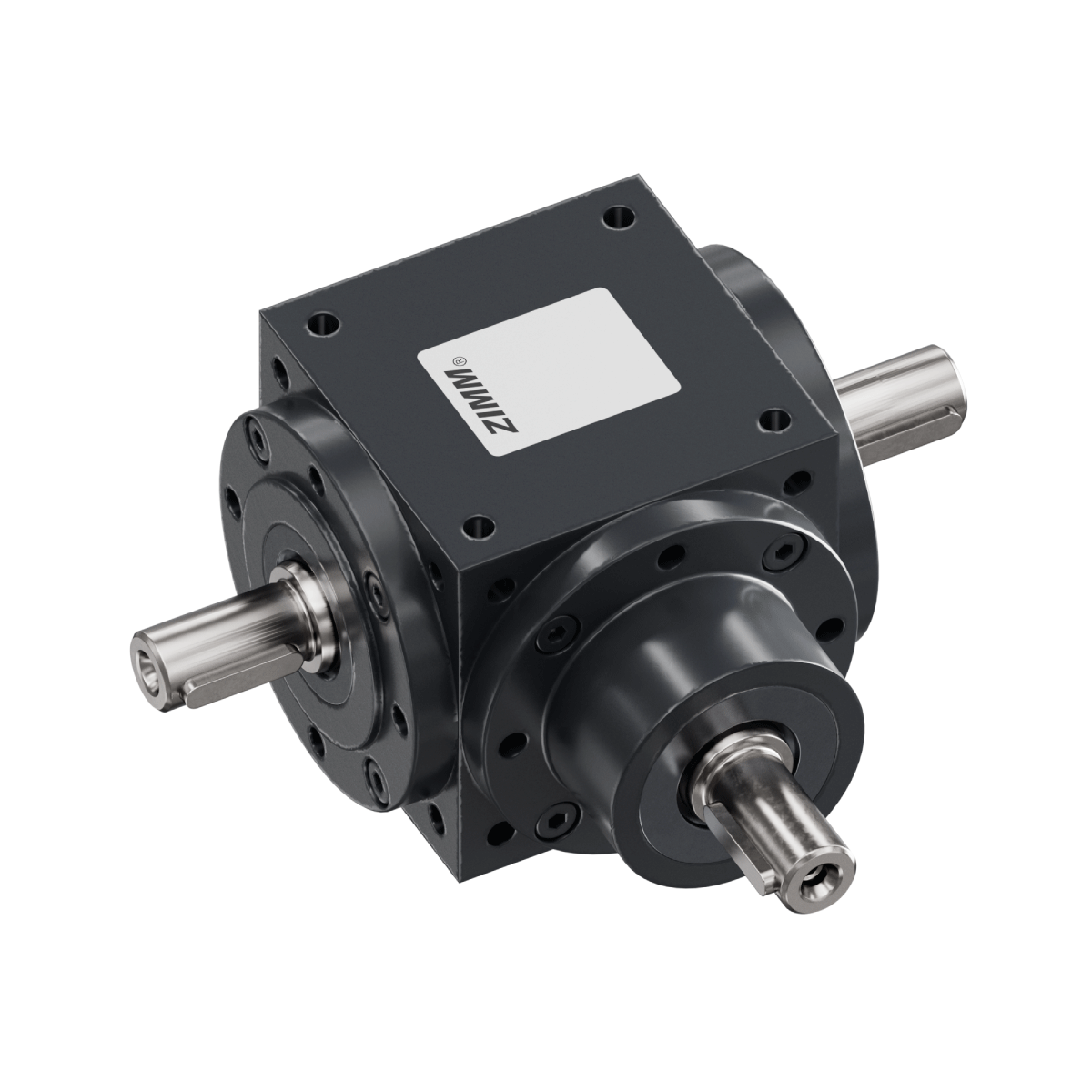

1. For type 1.1 / 1.2 / 1.3 / 1.3-HW

2. Relevant for orientation vertical shaft observe speed limitation

3. Alternative materials on request

4. Form AS for high dirt loads on request

|

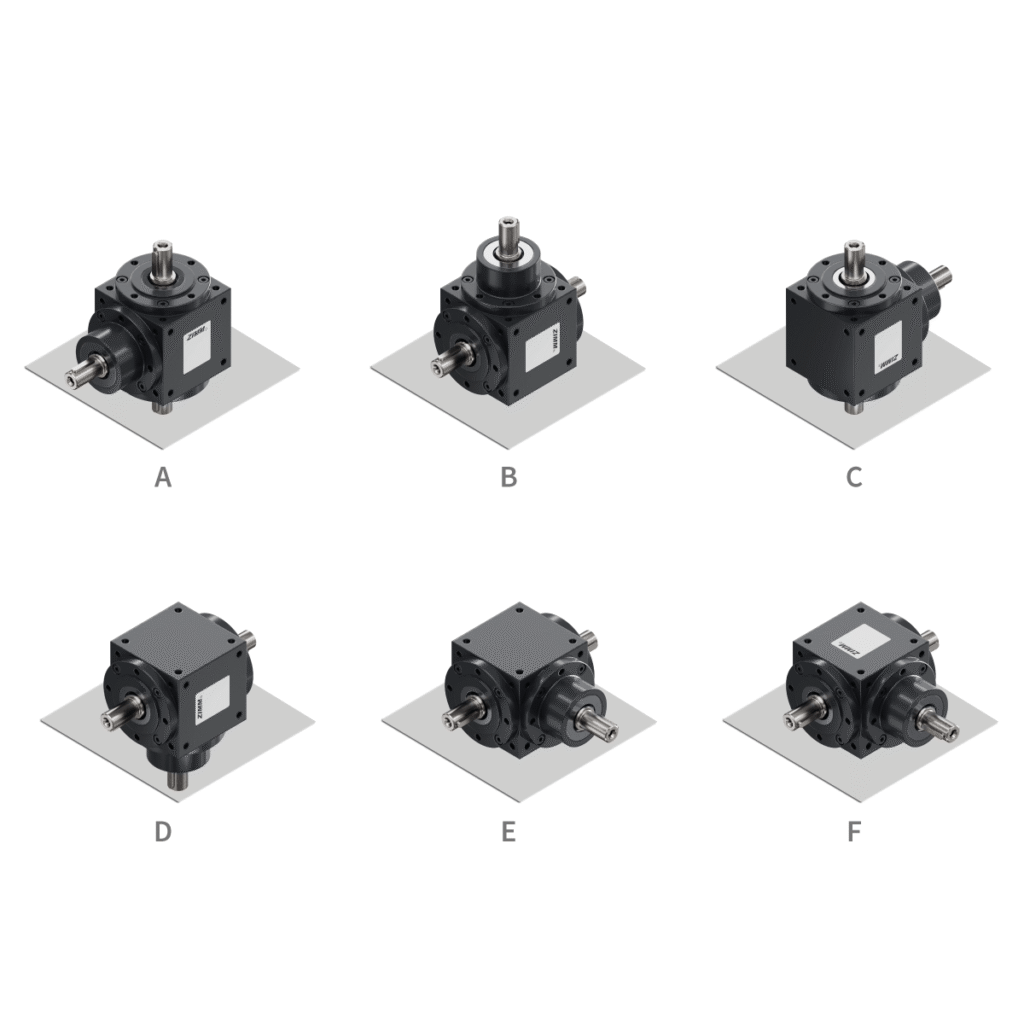

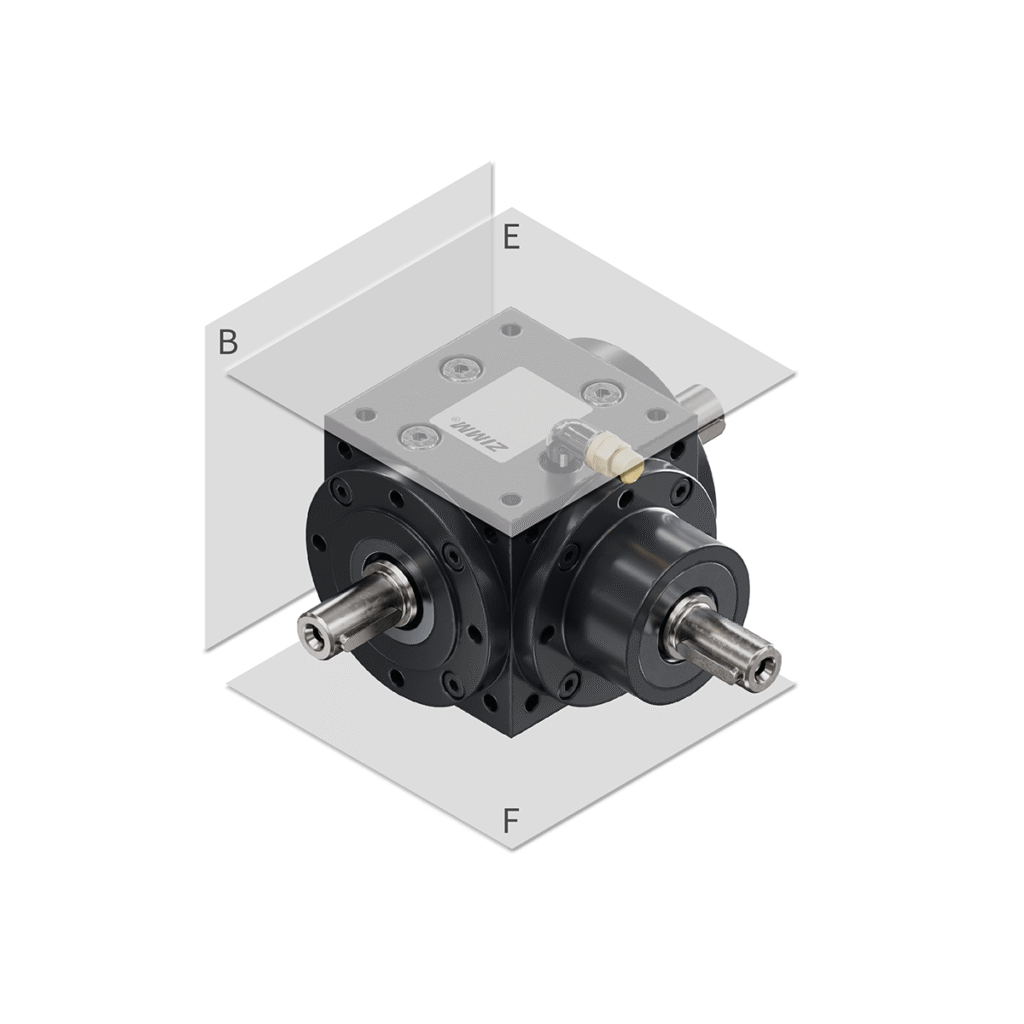

1.1 Output shaft at bevel gear (side C) |

|

1.2 Output shaft opposite to bevel gear (side A) |

|

1.3 Output shaft on both sides (side A+C) |

|

WE-FN Drive shaft: solid shaft | Output shaft: solid shaft |

|

HW-FN Drive shaft: solid shaft | Output shaft: hollow shaft |

| 64D | |

| High-tensile aluminium (INOX on request) | |

| 99 mm | |

| 3000 mm |

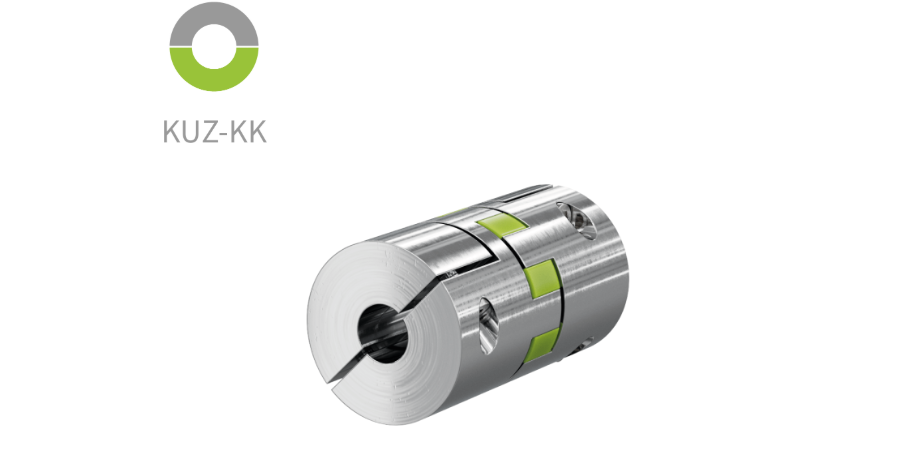

By using split shell couplings, the connecting shafts can be mounted after the drive shafts have been installed. Simply place the connecting shaft on the spigot and fix the couplings with torque wrench.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

| 92A, 55D, 98A | |

| Alumnium | |

| sintered steel | |

| cast iron |

| 64D | |

| High-tensile aluminium |

| No-load speed | ~1500 min-1 (other on request) |

|---|---|

| 64D | |

| Alumnium | |

| Operating voltage 230V delta | motor winding 230/400V |

| Operating voltage 400V star | motor winding 440/660V |

| Three-phase AC motors | IP 55 |

| Three-phase AC motors with brakes | IP 54 |