Your basket is currently empty!

Which lubricant is the right one and how is it applied?

Is there a topic missing?

Despite our comprehensive wiki, you haven’t found the information you’re looking for? Then don’t hesitate to contact us directly.

Our team will be happy to help you personally – whether it’s specific applications, custom-made products or missing content. Together we will find the right solution.

Author:

Last modified:

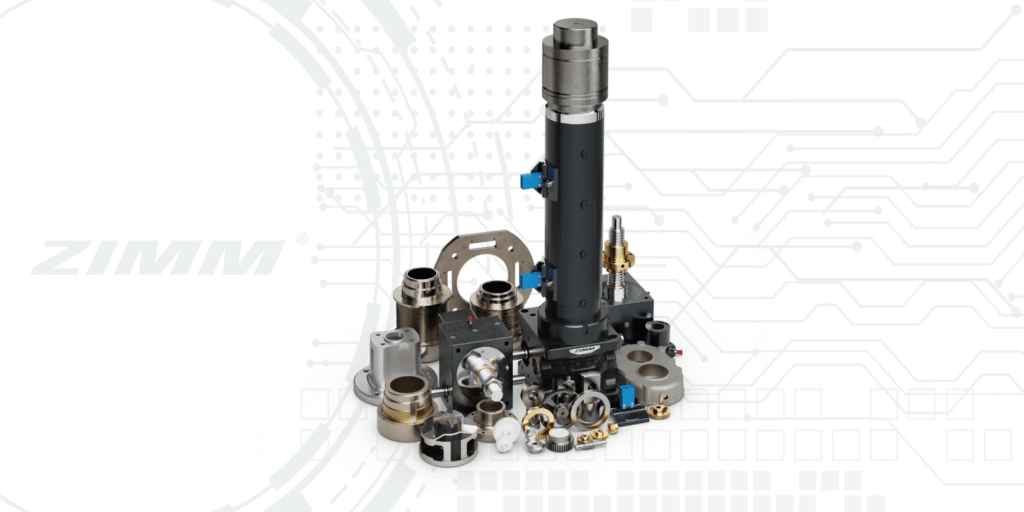

The decisive component that determines friction, wear and the service life of your drive.

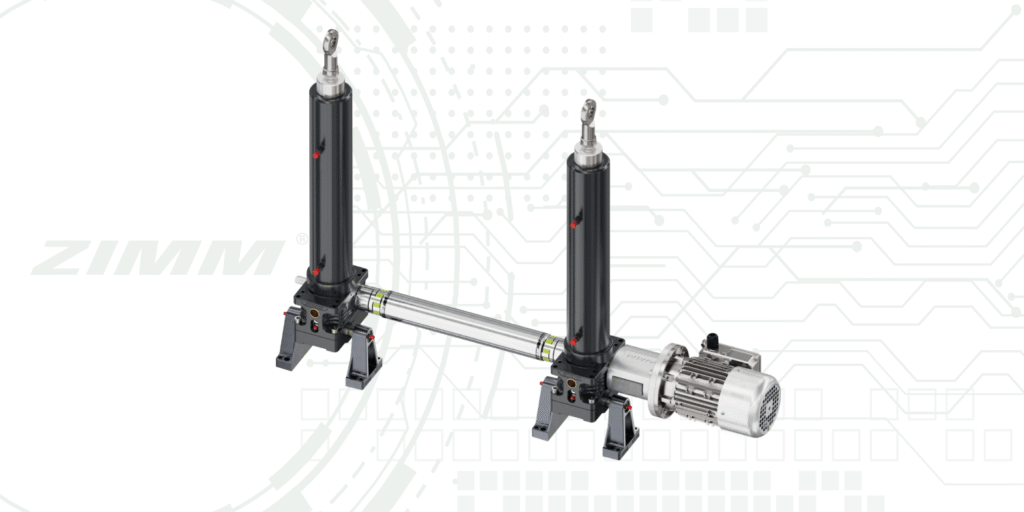

Choosing the right lubricant is one of the most important factors for the service life and reliable operation of a screw jack. The lubricant forms a protective film between metallic surfaces, reduces friction and wear, dissipates heat and protects against corrosion. An unsuitable lubricant can lead to significantly increased wear, malfunctions and premature failure – and in extreme cases impair warranty claims. A clear, unambiguous lubrication recommendation is therefore an essential contribution to the safe use of screw jack systems.

Different requirements for different components

It is important to understand that the different subassemblies of a screw jack place different demands on the lubricant. As a rule, there is no “one grease for everything”.

- Trapezoidal screw (TR): High surface pressure and sliding friction require greases with very good emergency-running properties and high load-carrying capacity (EP additives).

- Ball screw drive (KGT): Rolling friction and often higher speeds require a grease that wets the balls well, ensures stable lubricant film formation and remains consistent even in continuous operation.

- Gearbox (worm wheel/worm shaft): Here, a semi-fluid grease is usually used that distributes well inside the housing and reliably lubricates the tooth flanks.

ZIMM lubricant guide for screw jack systems

The following overview shows typical lubricant types for different applications. The products mentioned serve as examples; decisive are always the approvals and information in the operating instructions.

| Application area | Component | Recommended lubricant type / example product |

| Standard | Trapezoidal screw (TR) | Mineral EP grease (e.g. Tribol GR 4020/460-2 PD) |

| Standard | Ball screw (KGT) | Synthetic grease (e.g. Tribol GR 4747/220-2) |

| Standard | Gearbox (ZE / GSZ series, up to size 200) | Synthetic semi-fluid grease (e.g. Optileb GR UF 00) |

| High temperature (50–100 °C) | Trapezoidal screw (TR) | Synthetic grease (e.g. Tribol GR 4747/220-2) |

| High temperature (50–100 °C) | Ball screw (KGT) | Special PFPE-based grease (e.g. SYN-Setral-INT/250 S-2) |

| High temperature (50–100 °C) | Gearbox (ZE / GSZ series) | Special PFPE-based semi-fluid grease (e.g. SYN-Setral-INT/250 S-0) |

| Low temperature (–30 °C to +30 °C) | Trapezoidal screw (TR) | Synthetic grease (e.g. Tribol GR 4747/220-2) |

| Low temperature (–30 °C to +30 °C) | Ball screw (KGT) | In many cases identical grease as standard (already synthetic) |

| Low temperature (–30 °C to +30 °C) | Gearbox (ZE / GSZ series) | Synthetic semi-fluid grease (standard) |

| Food industry (NSF-H1) | Trapezoidal screw (TR) | Synthetic food-grade grease (e.g. Tungrease CP-2) |

| Food industry (NSF-H1) | Ball screw (KGT) | Synthetic food-grade grease (e.g. Tungrease CP-2) |

| Food industry (NSF-H1) | Gearbox (ZE / GSZ series) | NSF-H1 approved semi-fluid grease according to manufacturer release |

Note: The specific approvals, viscosity grades and product designations in the respective ZIMM operating instructions are always decisive.

How is the lubricant applied?

- Gearbox: Gearboxes are usually filled at the factory. Relubrication or grease change is carried out via the designated grease nipples or fill/drain plugs. Only approved lubricants may be used and the fill quantities from the documentation must be observed.

- Lifting screw (TR / KGT): Clean the screw before relubrication (remove contamination and old grease residues). Apply the grease evenly to the thread; during movement, the lubricant film is distributed in the nut. Some nuts have lubrication holes: here, grease can be pressed directly into the nut, which ensures very good internal distribution. Separate lubrication lines allow separate lubrication where required, which can be topped up during operation.

- Important practical note:

- On unprotected screws (without bellows/cover), no “ridge” of grease should be applied, as an excessively thick lubricant film will attract and retain dirt and dust.

- The screw should only be lightly and evenly coated – in combination with suitable protection (e.g. bellows), this is the best basis for low friction and a long service life.

- Consistently selecting lubricants to match the application and environment, combined with the correct application technique, is therefore one of the most effective levers for operating your screw jack system reliably and economically over the long term.