Your basket is currently empty!

Which environmental conditions must be taken into account?

Is there a topic missing?

Despite our comprehensive wiki, you haven’t found the information you’re looking for? Then don’t hesitate to contact us directly.

Our team will be happy to help you personally – whether it’s specific applications, custom-made products or missing content. Together we will find the right solution.

Author:

Last modified:

A critical aspect of system design that determines the durability and reliability of the drive in real-world operation.

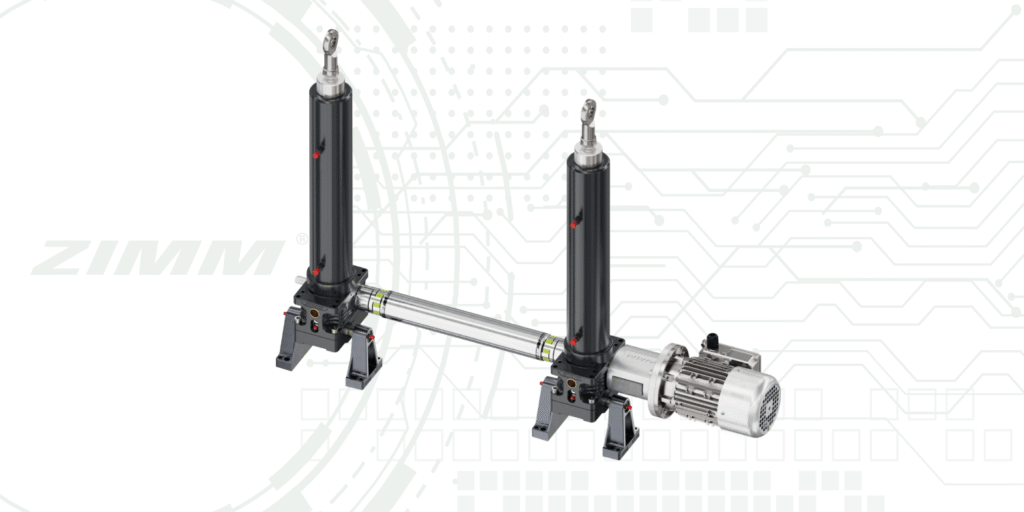

Screw jacks are used in very different environments – from clean indoor areas to harsh industrial and outdoor conditions. Considering the environmental conditions at an early stage is crucial for selecting and configuring the drive system in order to avoid corrosion, premature wear and unplanned downtime.

Temperature

Most screw jacks are designed for a temperature range of approx. –20 °C to +80 °C.

- Low temperatures: Below freezing, the viscosity of the lubricating grease increases significantly. This raises the starting and no-load torque and can limit the achievable speed. For such applications, special low-temperature greases based on synthetic oils are required that maintain their lubricating properties at low temperatures.

- High temperatures: Near furnaces or at high duty cycles, the lubricant must be thermally stable. High-temperature greases are used in these cases. At the same time, it must be ensured that the operating temperature of the gearbox does not exceed the permissible limits so that seals and lubricant are not damaged.

Humidity and corrosion

- Standard version: Painted standard gearboxes provide basic corrosion protection in typical industrial environments.

- High humidity / spray water: In humid environments, outdoor applications or areas with regular cleaning, additional corrosion protection measures are advisable, for example:

- Stainless steel screws to prevent rust on the lifting screw

- Special coatings or stainless-steel housings

- Improved sealing to prevent moisture from entering the gearbox

Contamination, dust and abrasive particles

- Risk: Contamination, dust, sand, metal chips or other particles on the lifting screw act like grinding paste. They are drawn into the nut during movement and lead to rapid wear of the thread and seals.

- Protective measures: The most effective measure is a bellows or a spiral spring cover band that encloses the screw and protects it from contamination. In heavily contaminated environments, such covers are virtually a prerequisite for a long service life.

Aggressive media and special requirements

- Chemicals: In the chemical industry or electroplating plants, vapours and liquids can attack the materials. Chemically resistant materials (e.g. special stainless steels) and suitable sealing materials (e.g. Viton) must be selected here.

- Food industry: Stricter hygiene requirements apply. Systems must be easy to clean; smooth surfaces, stainless-steel designs and food-grade lubricants (e.g. with NSF H1 approval) are standard.

- Cleanroom / vacuum: Applications in semiconductor manufacturing, laboratories or in vacuum environments require low-outgassing materials and specially matched lubricants; custom designs are often necessary.

A careful analysis of the environmental conditions in advance makes it possible to configure a screw jack that operates reliably and with a long service life even under demanding conditions – thereby ensuring the availability of the entire system.