Your basket is currently empty!

What is self-locking in screw jacks and when is it important?

Is there a topic missing?

Despite our comprehensive wiki, you haven’t found the information you’re looking for? Then don’t hesitate to contact us directly.

Our team will be happy to help you personally – whether it’s specific applications, custom-made products or missing content. Together we will find the right solution.

Author:

Last modified:

A fundamental principle that ensures mechanical safety without external energy.

Self-locking describes the ability of a screw drive to safely hold an axial load without any external braking force – even when the drive is switched off. The holding effect is created purely mechanically by the friction in the thread flanks. This is a key safety feature in particular for trapezoidal screw drives (TR) to prevent uncontrolled lowering in the event of a power failure or system shutdown. In applications with ball screw drives (KGT), there is fundamentally no self-locking due to the very low friction – here a motor brake is required.

How does self-locking work?

Self-locking occurs when the friction-based holding forces in the thread are greater than the driving force component resulting from the load acting via the inclined plane of the thread flank. The decisive parameter is the lead angle of the screw:

- Small lead angle (shallow thread): high friction component → self-locking.

- Large lead angle (steep thread): the driving component overcomes the friction → not self-locking, the load would run back.

(Note: The effective self-locking capability additionally depends on the coefficient of friction, lubrication, temperature and surface condition.)

Static vs. dynamic self-locking

- Static self-locking: The system holds a load starting from standstill. It does not actively brake a movement that is already in progress. This is typical for lead angles of approx. 2.4° to approx. 4.5° (guide value depending on friction coefficient and lubrication).

- Dynamic self-locking: The system can slow down a movement that is already in progress and bring the load to a standstill by itself. This is the safest case and occurs at very small lead angles (< approx. 2.4°).

At lead angles > approx. 4.5°, self-locking is generally no longer present. KGT, due to rolling friction, are in principle not self-locking and always require an external brake for load-holding.

When is self-locking important?

Self-locking is crucial whenever unintentional lowering could endanger people, machinery or product. Typical use cases:

- Lifting tables, work platforms

- Sluice gates, shut-off devices

- Format adjustment and positioning units that must hold position for long periods

- Safety-critical lifting applications (multi-point, high loads)

Note: Vibrations or shocks can impair static self-locking. In highly critical or dynamically loaded applications, it is common practice to provide a motor brake and/or safety components (e.g. safety nut, limit switches/encoders) in addition to (possible) self-locking for redundancy. Expert design of the safety concept is part of system planning.

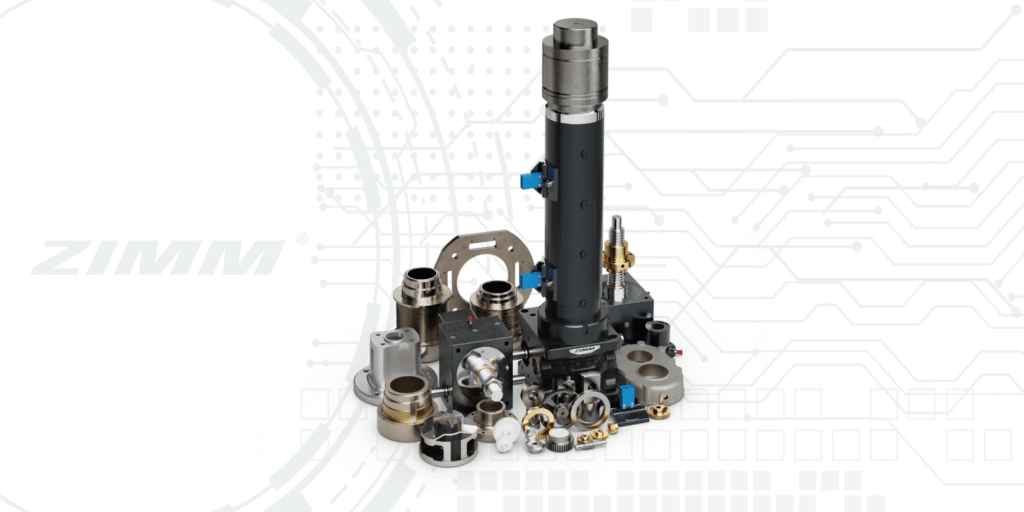

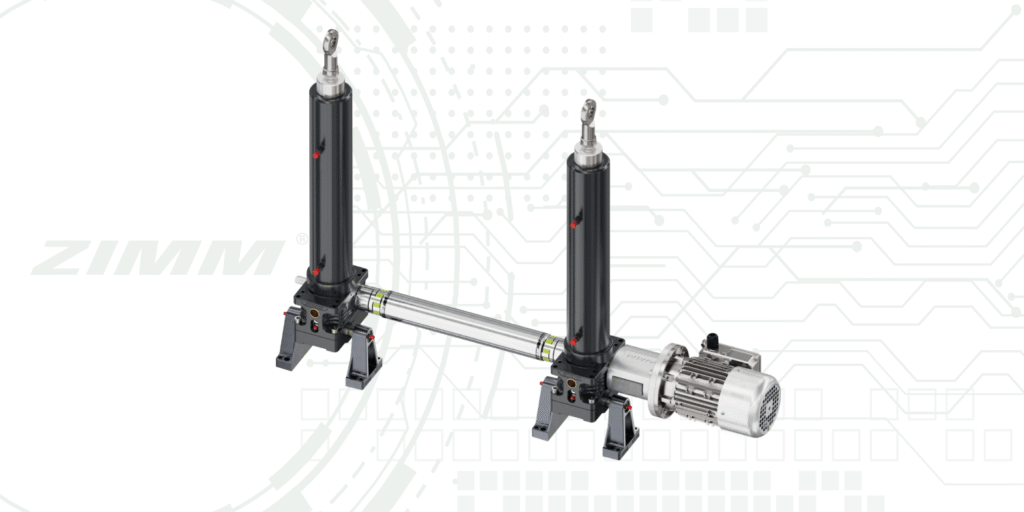

ZIMM practical context (modular system & design)

- Screw jacks (TR) in the ZIMM modular system offer static/dynamic self-locking depending on the lead – ideal where load-holding without power supply is required.

- KGT-based solutions provide dynamics and efficiency, but require a brake/safety chain for holding.

- For multi-point lifting systems (e.g. H-configuration), ZIMM combines screw jacks, bevel gearboxes, connecting shafts and couplings into mechanically synchronised overall systems – including protective components (e.g. bellows, safety nuts) and sensors (limit switches/encoders).

Best practice: Precise alignment, correct assembly sequence, suitable lubrication → increases service life and safety margin.

Short conclusion

- Use self-locking (TR) when safe holding without energy is the top priority and movements are infrequent/slow.

- Use KGT + brake when high precision, dynamics and high duty cycle (ED) are required.

- Redundancy (e.g. motor brake, safety nut, safety limit switches) is state of the art in critical applications.