Your basket is currently empty!

What is a screw jack system?

Is there a topic missing?

Despite our comprehensive wiki, you haven’t found the information you’re looking for? Then don’t hesitate to contact us directly.

Our team will be happy to help you personally – whether it’s specific applications, custom-made products or missing content. Together we will find the right solution.

Author:

Last modified:

The intelligent complete solution that turns individual drive components into a precise and reliable motion system.

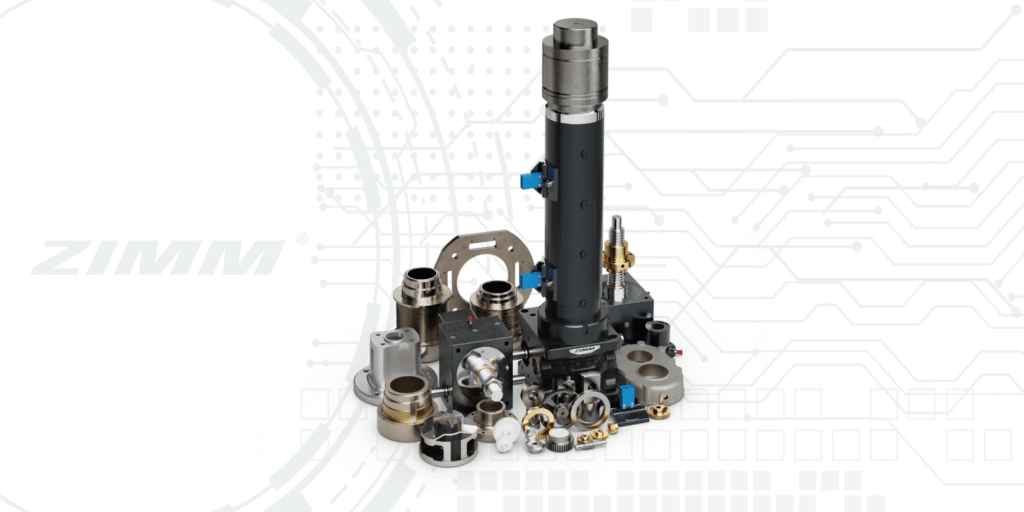

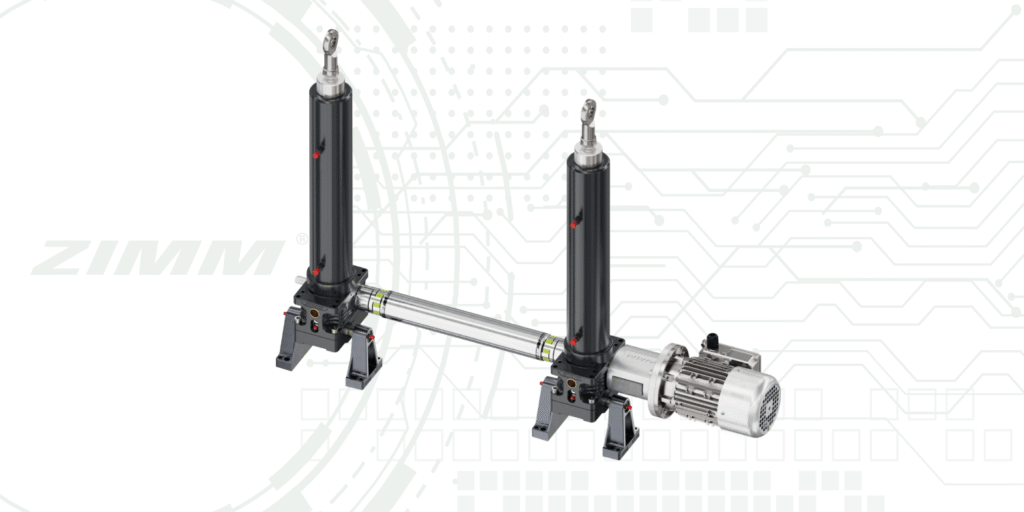

A screw jack system is a fully designed and integrated installation for controlled, synchronised movement of loads – often at multiple points and with high repeat accuracy. It goes beyond simple component procurement and delivers a function-guaranteed solution in which mechanics, electrics and control system are combined into one unit. The system provider takes care of design, component selection and integration – from screw jacks and bevel gearboxes to connecting shafts and couplings, through to the protection and accessory programme of the ZIMM modular system.

The core components of a screw jack system

A typical system has a modular design and includes:

- Screw jacks: One or more ZIMM screw jacks (e.g. ZE/ZE-H/GSZ) perform the lifting work and form the basis for precise lifting and positioning.

- Drive motor: A central electric motor provides the rotational energy (controlled by a frequency inverter depending on the application).

- Mechanical connecting elements: Distribute the motor power to all lifting points:

- Bevel gearboxes (e.g. KSZ-H, KST) for 90° redirection and distribution in T- or L-arrangements; symmetrical design makes it easier to change the direction of rotation.

- Connecting shafts (e.g. VWZ) for bridging distances, with split-shell couplings for quick installation in the assembled state.

- Couplings (e.g. KUZ) for backlash-free, damping connection and to compensate for minor misalignments.

- Control system and sensors: Frequency inverter/PLC, limit switches or encoders for speed and position monitoring as well as safe shutdown. (The ZIMM Wiki recommends, among other things, precise alignment of all gearboxes before attaching shafts/couplings to ensure smooth, low-wear operation.)

- Operating elements: Pushbuttons or operator panel for convenient operation.

- Accessories and add-on parts: Mounting elements, bellows, safety nuts, suitable spindle ends and add-on parts – for fast system integration from a single modular kit.

Through the interaction of these coordinated components, a robust, precise system is created for complex lifting and positioning tasks – from mechanical and plant engineering through material handling/conveying technology to stage technology. Practical examples in the ZIMM environment range from multi-point synchronised lifting platforms to vehicle-carrying lifting systems with safety components.

Category:

Questions and answers about our products