Your basket is currently empty!

What is a screw jack and how does it work?

Is there a topic missing?

Despite our comprehensive wiki, you haven’t found the information you’re looking for? Then don’t hesitate to contact us directly.

Our team will be happy to help you personally – whether it’s specific applications, custom-made products or missing content. Together we will find the right solution.

Author:

Last modified:

The technology that turns rotation into precise motion – safe, efficient, and controlled.

A screw jack is an electromechanical drive that converts rotary motion (rotation) into linear motion (translation). Its main task is to lift, lower, move, or position loads with precision. It is more than just a simple actuator: as an integrated system for precise and safe power transmission, its design enables high force amplification and reproducible positioning accuracy.

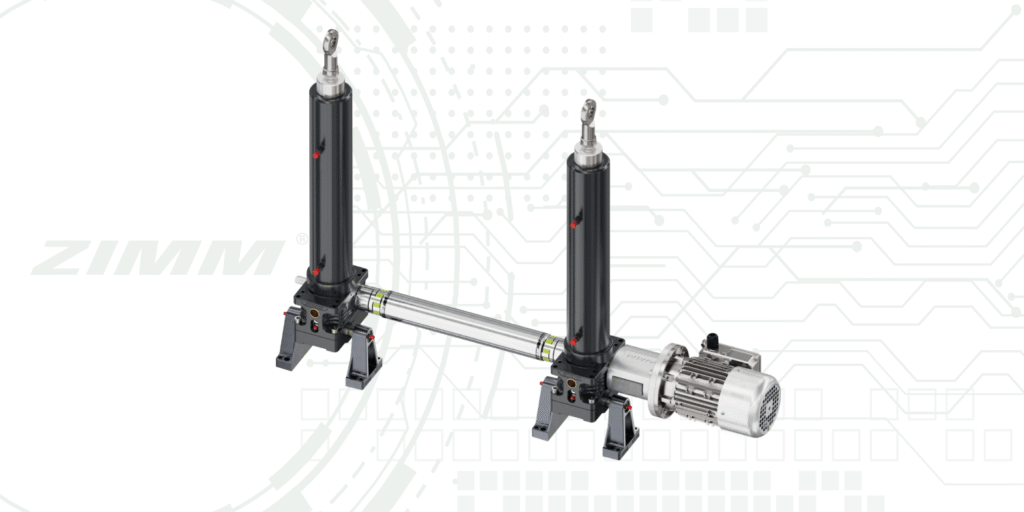

ZIMM offers proven solutions for this in various series and sizes – including the S version (translating spindle) and R version (rotating spindle with travelling nut) – covering a wide range of loads.

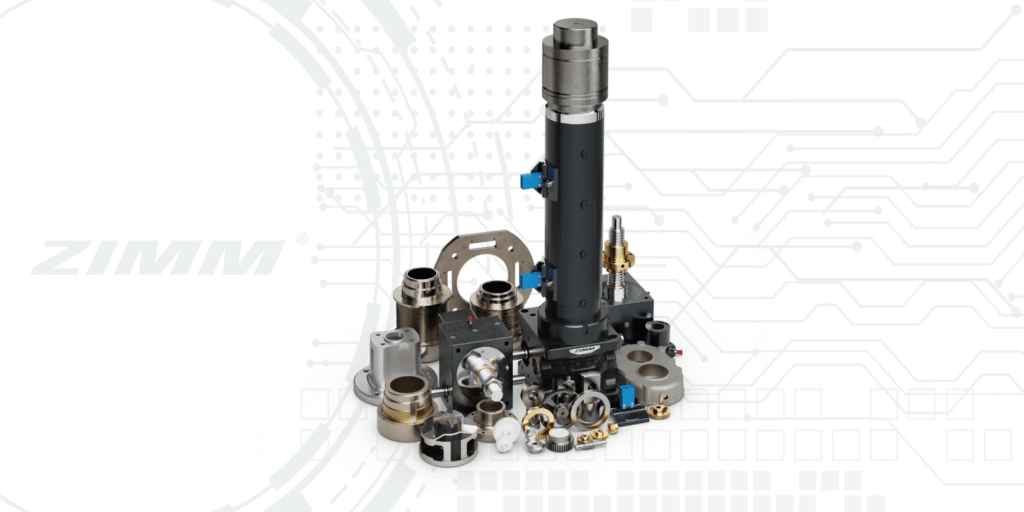

Design and key components

The heart of a screw jack consists of a few robust components housed in a gearbox:

Housing

It protects the internal components, provides mounting, and supports heat dissipation. Depending on the series, ZIMM uses classical designs derived from worm gear units as well as flexibly mountable, cubic housings; they are designed for high power density, smooth running, and durable corrosion protection.

Worm shaft (input shaft)

It is driven by a motor (e.g. servo or asynchronous motor) and transmits the rotary motion to the worm wheel.

Worm wheel

This gear is driven by the worm shaft. It has an internal thread and acts as a precisely guided nut for the screw – the basis for friction-locked, backlash-free conversion to linear motion.

Lifting screw (threaded screw)

It generates the actual linear motion. Depending on the requirements, trapezoidal screw drives (robust, self-locking) or ball screw drives (high efficiency, low friction) are used – for precise control, repeat accuracy, and high efficiencies.

The basic operating principle

The function of a screw jack is based on the principle of a worm gear, which achieves a high gear reduction in a compact installation space. This design is a key feature for force amplification: a small, cost-efficient standard motor can thus move large loads precisely – lifting, lowering, or positioning them. In ZIMM terminology, two main variants are distinguished, both of which convert the motor’s rotary motion into linear lifting motion.

Basic version (translating spindle / S version)

The motor drives the worm shaft, which in turn moves the worm wheel in the housing. The lifting screw is prevented from rotating (e.g. by the connected load) and moves axially up or down through the rotating internal thread of the worm wheel – the screw extends from and retracts into the gearbox. This version is robust, self-locking (with trapezoidal screw), and the first choice for many adjustment tasks.

Travelling nut version (rotating spindle / R version)

Here the lifting screw is connected to the worm wheel and rotates with it. The linear motion is provided by an external travelling nut that runs along the screw thread while the screw itself maintains its axial position. This variant enables high lifting speeds and efficiency – especially in combination with ball screw drives – and can be integrated into systems in a modular way.

This mechanical conversion and amplification makes screw jacks a reliable, precise, and economical solution for a wide range of industrial applications where controlled force and exact positioning are required. ZIMM supplements this with suitable safety and system components (e.g. safety nut, accessories from the ZIMM modular system), so that complete, scalable lifting systems can be implemented quickly.

Category:

Questions and answers about our products