Your basket is currently empty!

What is a bevel gearbox and where is it used?

Is there a topic missing?

Despite our comprehensive wiki, you haven’t found the information you’re looking for? Then don’t hesitate to contact us directly.

Our team will be happy to help you personally – whether it’s specific applications, custom-made products or missing content. Together we will find the right solution.

Author:

Last modified:

The indispensable building block for power distribution and change of direction in complex drive systems.

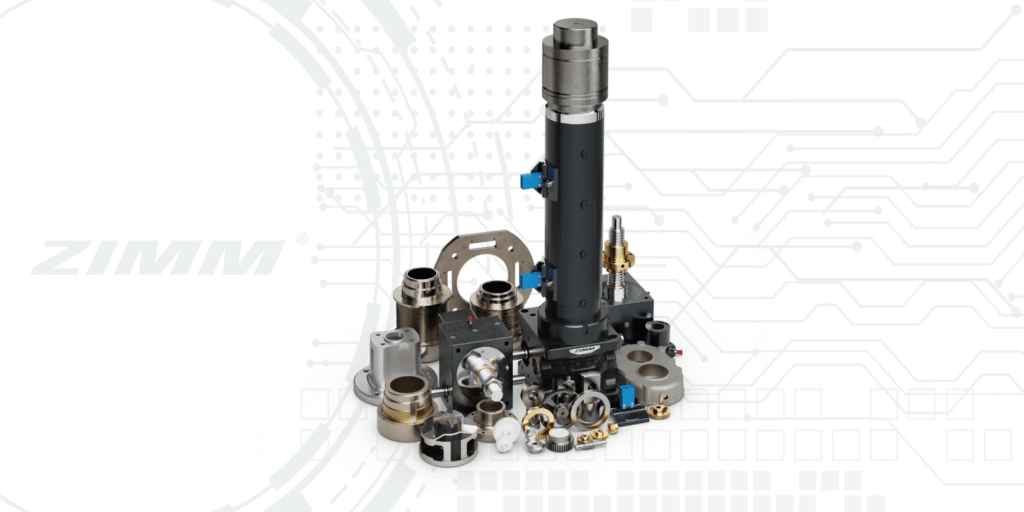

A bevel gearbox is a form of right-angle gearbox that transmits rotational movement and torque between intersecting shafts – typically at 90°. It is named after the conical gears (bevel gears) that provide the change in direction and gear ratio. In the ZIMM product range, this includes, among others, the KST and KSZ-H series with compact sizes, high torque density and symmetrical mounting dimensions.

While a screw jack moves a single linear axis, the bevel gearbox acts as an architectural distribution and deflection element: it links drives into a mechanically synchronised overall system – scalable, modular and compatible with the ZIMM modular system (screw jacks, actuators, shafts, couplings).

Design and operating principle

A bevel gearbox essentially consists of two main components:

- Driving bevel gear (pinion): smaller bevel gear on the input shaft.

- Driven bevel gear (crown wheel): larger bevel gear on the output shaft.

When the input shaft rotates, the pinion meshes with the crown wheel; the output motion is deflected through 90°. Depending on the tooth form (straight, helical or spiral bevel), smooth running, torque capacity and noise behaviour vary. ZIMM uses backlash-free tapered roller bearing support, effective sealing (shaft seals/O-rings) and high-precision gearing; available features include, among others, gear ratios of 1:1, 2:1, 3:1 and a rotatable, symmetrical design (e.g. 180° rotation to change the direction of rotation).

Use in screw jack systems

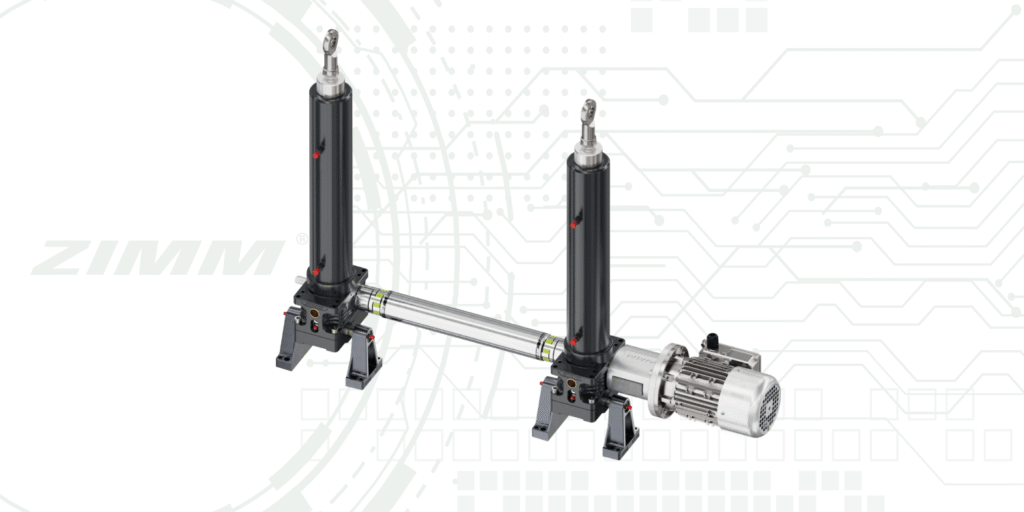

In screw jack systems, the bevel gearbox assumes the central distribution and deflection function – it distributes the power of one motor to several screw jacks. A typical arrangement looks like this:

- One motor drives a central connecting shaft.

- T-shaped bevel gearboxes are mounted along this shaft.

- Each bevel gearbox deflects through 90° and drives the worm/input shaft of a screw jack.

- The mechanical coupling ensures synchronised, uniform motion of all screw jacks involved – without complex electronic control. This enables large lifting systems, lifting platforms or precise adjustment systems (e.g. H-configuration with four screw jacks) that move as a single unit. For this purpose, ZIMM offers matched KSZ-H/KST bevel gearboxes, connecting shafts and couplings – fully compatible with screw jacks (ZE/ZE-H/GSZ) and actuators.

Beyond use in such systems, bevel gearboxes are widely used in mechanical and plant engineering, in conveying technology and in the automotive industry – wherever compact change of direction, high torque transmission and precise power distribution are required. ZIMM cites, among others, high efficiency, smooth running, backlash-free bearing support and robust housings (e.g. EN-GJL-250 or EN AW-6082 T6) as key product features.

Category:

Questions and answers about our products