Your basket is currently empty!

What is a ball screw (KGT) and how does it work?

Is there a topic missing?

Despite our comprehensive wiki, you haven’t found the information you’re looking for? Then don’t hesitate to contact us directly.

Our team will be happy to help you personally – whether it’s specific applications, custom-made products or missing content. Together we will find the right solution.

Author:

Last modified:

High performance for low-friction, precise and fast linear motion.

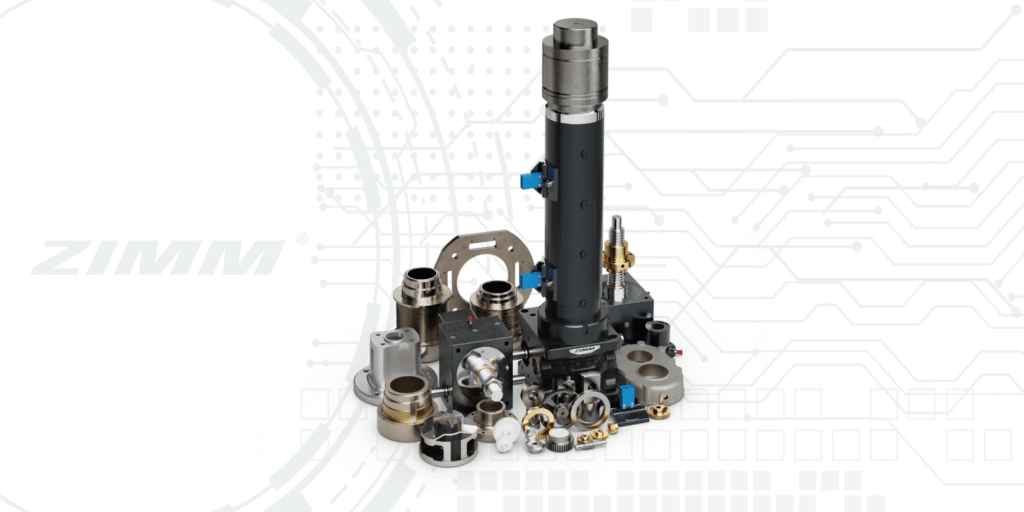

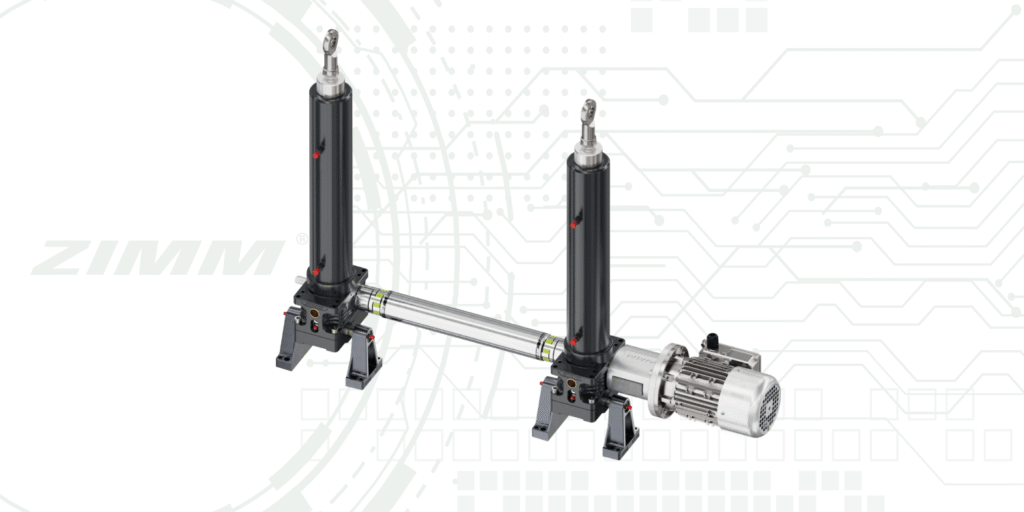

A ball screw (KGT) converts rotary motion with minimal friction into highly precise linear motion – or vice versa. It is regarded as a further development of classical screw drives, because sliding friction is replaced by rolling friction. The result fits perfectly with ZIMM’s modern electromechanical systems: energy-efficient, dynamic and exactly positionable – e.g. in screw jacks (ZE/ZE-H/GSZ) and actuators (ZA).

Operating principle: Rolling instead of sliding

In contrast to the trapezoidal screw drive, where the screw and nut slide on the flanks, the ball screw uses steel balls as rolling elements. These balls move in precise raceways between screw and nut and significantly reduce friction and heat generation.

This is how the mechanism works

- Motion: When the screw rotates, the balls roll in the thread grooves – the nut then performs a linear motion.

- Ball return: At the end of the raceway, the balls are returned via a return system. The closed circuit enables continuous, low-friction motion.

Main characteristics and advantages

The change from sliding to rolling friction leads to key benefits:

- Very high efficiency: Ball screws work significantly more efficiently than trapezoidal screws – with lower energy consumption and reduced heat generation.

- Higher speeds & duty cycles: Thanks to the ball recirculation principle, higher operating cycles are possible; the duty cycle can be up to four times higher than with trapezoidal screws.

- High precision & freedom from backlash: By means of preload (e.g. double nut or oversized balls), axial play can be minimised – positioning and repeat accuracy increase. (ZIMM uses ball screws specifically for high-precision applications.)

- Long, predictable service life: The rolling motion reduces wear – important for dynamic applications and high cycle rates. (Correct lubrication ensures performance and service life.)

These characteristics make the ball screw the first choice in CNC machines, robotics, metrology and everywhere that speed, efficiency and precision matter. In ZIMM screw jacks and actuators, this turns a simple “lever” into a powerful precision actuator – made in Austria/EU.

Category:

Questions and answers about our products