Your basket is currently empty!

What are the decisive advantages of electromechanical drives over hydraulics and pneumatics?

Is there a topic missing?

Despite our comprehensive wiki, you haven’t found the information you’re looking for? Then don’t hesitate to contact us directly.

Our team will be happy to help you personally – whether it’s specific applications, custom-made products or missing content. Together we will find the right solution.

Author:

Last modified:

A technology shift that not only replaces components, but revolutionises overall machine performance and cost-effectiveness.

The decision in favour of electromechanical drives instead of traditional hydraulics or pneumatics is more than just a technical alternative; it is a strategic decision for higher efficiency, precision and sustainability. While fluid technology still has its justification in niche applications with extremely high forces, electromechanics offers a superior overall package for the vast majority of industrial motion tasks. Digital control (PLC/drive controller), exact positionability and clean operation without leakages raise performance to a new level. This has a positive effect on the entire value chain – from energy costs and maintenance budgets to product quality and occupational safety.

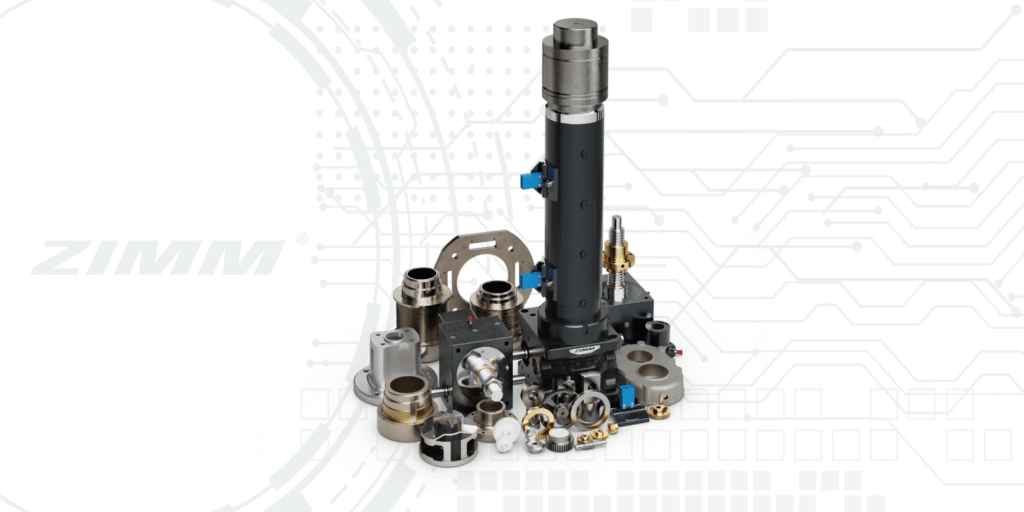

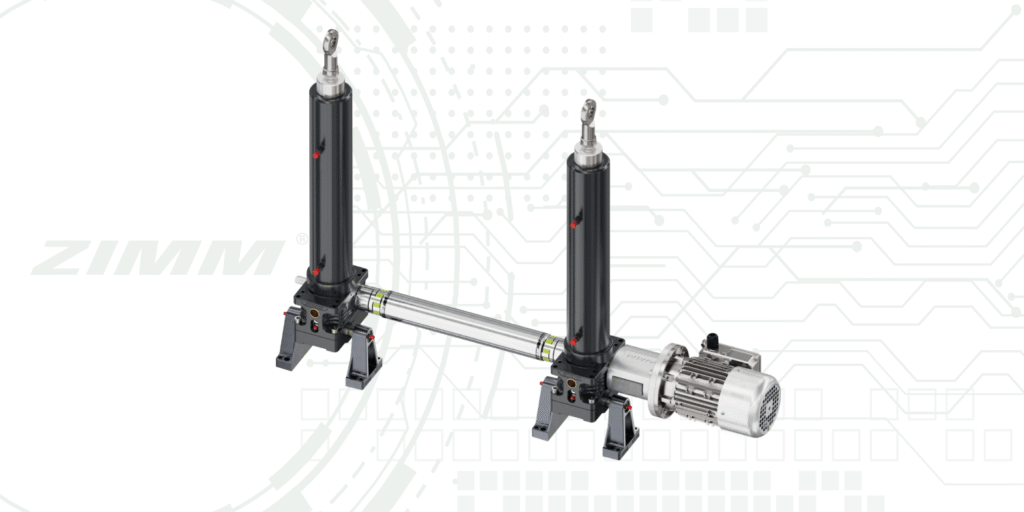

Our electromechanical actuators (ZA series) and screw jacks integrate modularly into the ZIMM modular system – including suitable drive technology, connecting elements, limit position monitoring and overload/crush protection. CAD data are available around the clock via the ZIMM CAD product configurator.

The following detailed comparison matrix, based on extensive analyses, shows the superiority of electromechanical systems in the key criteria.

| Criterion | ZIMM electromechanical systems | Hydraulic systems | Pneumatic systems |

| Energy efficiency | Very high. High overall efficiency, energy consumption only during motion, no standby losses. | Low. High losses; pump often needs to run continuously to maintain pressure. | Very low. Compressed air is an expensive form of energy; frequent leakage losses. |

| Precision & positioning accuracy | Very high. Exact, repeatable positioning without “drifting” – ideal for high-precision applications. | Rather low. Prone to drift due to leakages or temperature fluctuations; positioning accuracy is limited. | Limited. Compressibility of air makes exact intermediate positions difficult; end positions often precise. |

| Maintenance effort & service life | Low. Low-maintenance to maintenance-free; defined relubrication intervals, no oil or filter changes. | High. Regular oil/filter changes, inspection and replacement of seals and hoses; prone to leakages. | Moderate. Maintenance required on compressors, air treatment and leakage inspections. |

| Environmental compatibility & cleanliness | High. No hydraulic oil – no environmentally harmful leakages; low energy demand supports CO₂ reduction. | Low. Potential environmental impact due to oil leakages and disposal of used oil. | Medium. No fluid leakages, but energy-intensive compressed air generation; possible oil mist in the compressed air. |

| Noise emissions | Low. Electric motors and gearboxes operate significantly more quietly. | High. Hydraulic power units (pumps, valves) cause considerable noise pollution. | Medium to high. Hissing of escaping air as well as noise from compressors and valves. |

| System complexity & installation | Low. Few components (no pump, no tanks, no valves); compact design and simple installation. | High. Many components (pump, tank, filter, cooler, pipework); complex piping and commissioning. | Medium. Requires compressed air network and preparation units; hose routing to the cylinders. |

| Total Cost of Ownership (TCO) | Often lower in the long term. Lower energy costs, significantly less maintenance, reduced downtimes, higher productivity. | Often higher in the long term. High energy costs, intensive maintenance, costs for oil and filters as well as potential leakage and downtime costs. | Often higher in the long term. Very high energy costs for compressed air generation, maintenance of air preparation and leakage costs. |

Summary of the key advantages

A company that switches to electromechanics is not only investing in a better actuator, but in an overall more competitive, more sustainable and more cost-efficient production process. The main advantages are:

- Higher cost-effectiveness thanks to massive energy savings (high system efficiencies, no compressed air generation/oil circuits) and reduced maintenance effort (fewer components, no leakages).

- Better product quality thanks to maximum precision and repeatability in position, speed and force – ideal for process-reliable, documentable motion profiles.

- Increased productivity through higher travel speeds, reduced downtimes and digital diagnostics – from commissioning through to ongoing operation.

- Improved sustainability thanks to a clean, media-free drive, lower emissions and a reduced CO₂ footprint over the entire life cycle.

- Seamless integration into Industry 4.0 environments: simple connection to PLC/drive, ZIMM modular system for precisely matched mechanics, rapid design via the ZIMM CAD product configurator.

Category:

Questions and answers about our products