Your basket is currently empty!

What are the critical buckling load and critical speed and how are they calculated?

Is there a topic missing?

Despite our comprehensive wiki, you haven’t found the information you’re looking for? Then don’t hesitate to contact us directly.

Our team will be happy to help you personally – whether it’s specific applications, custom-made products or missing content. Together we will find the right solution.

Author:

Last modified:

Two fundamental stability checks that are essential for the safety and functionality of long lifting screws in screw jacks.

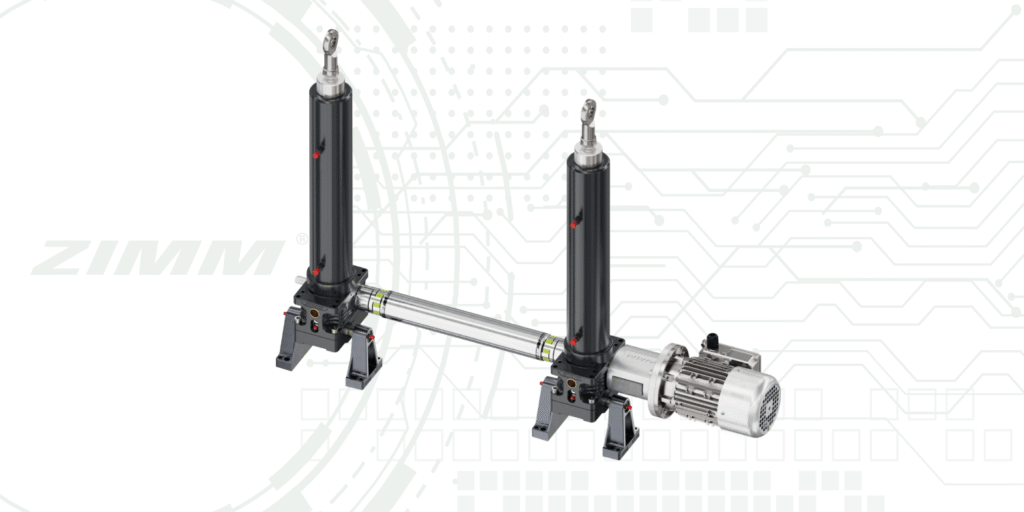

When designing screw jacks, especially for applications with long strokes, the load capacity of the gearbox and the motor power alone are not sufficient. Two additional physical limits of the screw itself must always be checked: the critical buckling load under compressive loading and the critical speed for rotating screws. Ignoring these limits can lead to deflection, vibrations and, in the worst case, failure of the system.

1. Critical buckling load

A long, slender screw subjected to high compressive force behaves like a column and can suddenly buckle sideways – long before the material itself would be overloaded. This effect is called buckling. The maximum compressive force a screw can withstand without buckling is the critical buckling load.

When is this check required?

Always when the screw is predominantly loaded in compression. For pure tensile loading there is no danger of buckling.

Calculation:

The buckling load is calculated using the Euler or Tetmajer formulas. It essentially depends on the following factors:

- Unsupported screw length (L): The maximum distance between the nut and the point where the screw is supported. This is the decisive influencing factor.

- Core diameter of the screw: (dkern): A screw with a larger core diameter is more resistant to buckling.

- Type of end support: The way in which the ends of the screw are supported (e.g. fixed–free, fixed–fixed) is taken into account via a correction factor.

The operating force should be at most about 80% of the permissible axial force, and the buckling safety factor (ratio of critical buckling load to operating load) should typically be between 3 and 6. Since the calculation is complex, technical manuals and catalogues usually provide diagrams from which the permissible compressive force can be read directly as a function of the free screw length.

2. Critical speed (nkrit)

A long, rotating screw (e.g. in travelling-nut versions) can enter into resonant vibration at a certain speed. The screw begins to deflect significantly and to “whip”. This speed is called the critical speed and must be avoided under all circumstances.

When is this check required?

Always for versions in which the screw rotates – in particular for travelling-nut designs and long lifting screws with higher speeds.

Calculation:

The critical speed depends on the same factors as the buckling load:

- Unsupported screw length (L): The distance between the support points of the screw.

- Core diameter of the screw (dkern): A stiffer, thicker screw permits higher speeds.

- Type of end support: The way the screw is supported is included in the calculation via a correction factor.

- Safety rule: The maximum operating speed should be at most about 80% of the theoretical critical speed in order to maintain a safe distance from the resonance frequency. Here too, technical manuals generally provide diagrams for simple determination of the permissible speed.

If the check shows that one of the limits is exceeded, design modifications must be made – such as choosing a screw with a larger diameter, changing the support conditions, adding intermediate supports or reducing the speed (e.g. via the screw lead). This keeps the system with screw jacks safe, stable and reliable across the entire operating range.