Your basket is currently empty!

How do I calculate the service life of a screw jack?

Is there a topic missing?

Despite our comprehensive wiki, you haven’t found the information you’re looking for? Then don’t hesitate to contact us directly.

Our team will be happy to help you personally – whether it’s specific applications, custom-made products or missing content. Together we will find the right solution.

Author:

Last modified:

A complex process that goes beyond simple formulas and takes real operating conditions into account.

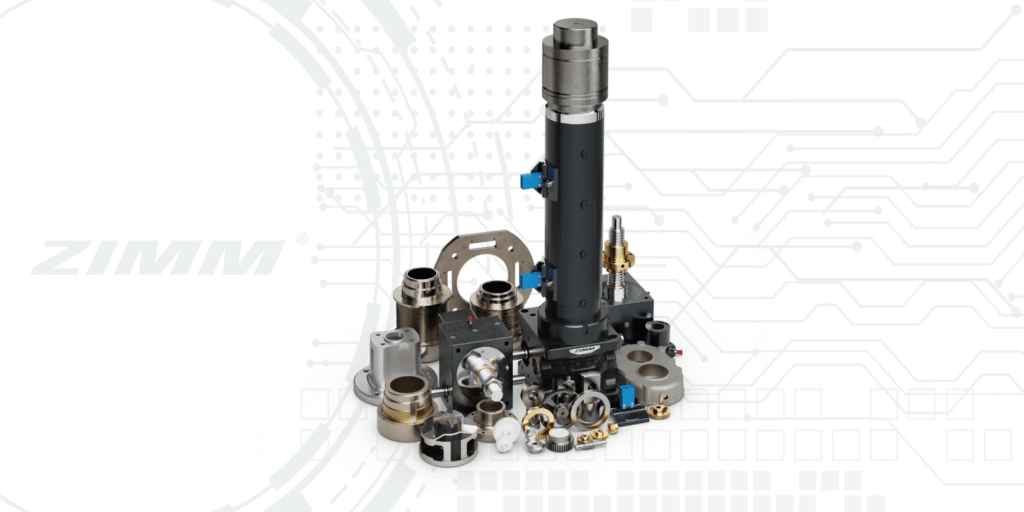

Calculating the expected service life of a screw jack is a complex task because it is influenced by a wide range of factors. Service life is usually not limited by sudden fracture, but by material fatigue and wear of the moving parts – primarily the rolling bearings and the screw drive (trapezoidal screw drive TR or ball screw drive KGT).

Factors influencing service life

The modern, extended method for calculating rolling bearing life according to ISO 281 takes into account a number of influences that go beyond the pure load. These principles can also be applied to the service life of the entire gearbox:

| Criterion | |

| Magnitude of the load | The most important variable. Higher load leads to an exponentially shorter service life. |

| Fatigue limit of the material | The load limit below which, theoretically, no material fatigue occurs. Materials with higher fatigue strength allow longer service lives. |

| Lubrication (viscosity ratio) | The quality of lubrication is crucial. An optimal lubricant film separates the metallic surfaces, drastically reduces wear and extends service life – especially when using suitable ZIMM lubricants and regular relubrication. |

| Cleanliness in the lubrication gap | Contaminants (particles) in the lubricant act like abrasives and can damage the surfaces of bearings and threads, leading to premature fatigue. Protective measures such as bellows have a life-extending effect here. |

| Speed | Influences the number of load cycles per unit time and the formation of the lubricant film – high speeds mean more load cycles in a shorter time. |

| Operating temperature | Affects the viscosity of the lubricant and the material properties and thus directly influences the achievable service life. |

The extended modified service life calculation (ISO 281)

The extended, modified service life calculation according to ISO 281 describes bearing life as: Lna = a₁ · aISO · L₁₀ where in practice:

- Lna = extended modified service life in millions of revolutions

- a₁ = life factor for reliability

- aISO = life factor that takes lubrication, contamination and fatigue limit into account

- L₁₀ = nominal life according to the basic formula

- Für L₁₀ the familiar ISO 281 relationship applies:

- L₁₀ = (C / P)p with

- C = dynamic load rating (a characteristic value of the bearing/gearbox)

- P = dynamic equivalent load (the actual load)

- p = life exponent (typically 3 for ball bearings/KGT, 10/3 for roller bearings).

- L₁₀ = (C / P)p with

Practical relevance for design

Accurate calculation of service life is very complex and requires detailed knowledge of the operating conditions. For the user, the following points are therefore key:

- Accurate application data: The more precisely load, speed, duty cycle and operating cycles are known, the more accurately service life can be estimated and the more precisely the screw jack can be sized.

- Cleanliness and maintenance: The theoretical service life can only be achieved if the system is kept clean and relubricated correctly. Protecting the screw with a suitable bellows and using appropriate ZIMM lubricants can significantly extend service life in dusty or harsh environments.

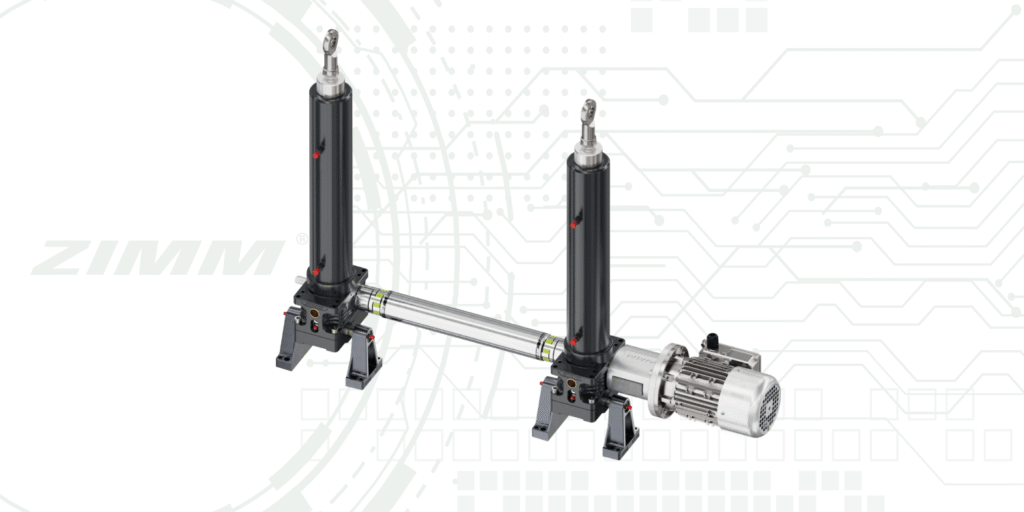

- Use manufacturer tools: For reliable design, the online configurators and calculation documents provided by manufacturers such as ZIMM should be used. These tools take the specific characteristics of the products into account and guide the user safely through the design process.

A realistic service life estimate is the key to sizing a drive that not only works, but performs its task reliably and economically over the entire life cycle of the machine.