Your basket is currently empty!

How are multiple screw jacks mechanically synchronised?

Is there a topic missing?

Despite our comprehensive wiki, you haven’t found the information you’re looking for? Then don’t hesitate to contact us directly.

Our team will be happy to help you personally – whether it’s specific applications, custom-made products or missing content. Together we will find the right solution.

Author:

Last modified:

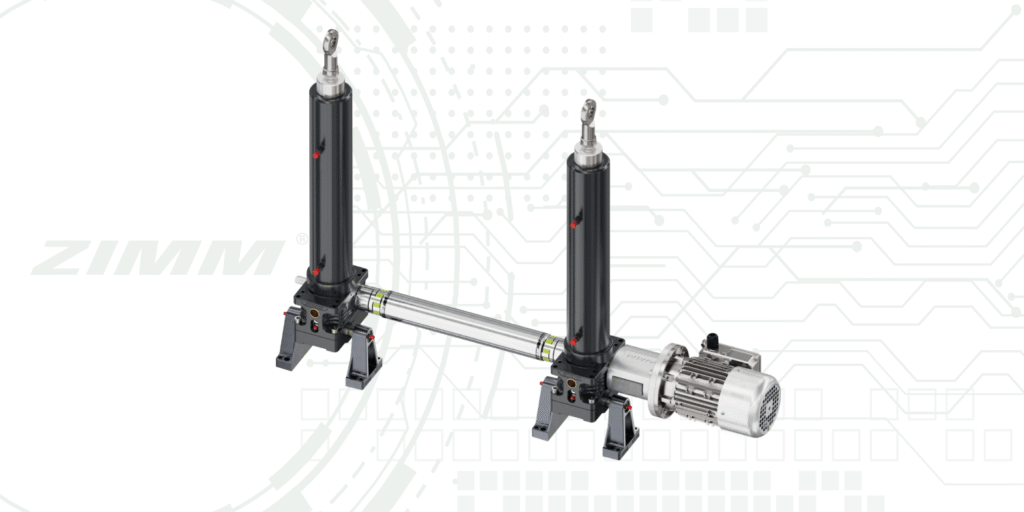

A robust and reliable principle that ensures absolute uniformity without complex electronics.

Mechanical synchronisation is one of the core strengths of screw jack systems in the ZIMM modular system. It makes it possible to move large, spatially distributed loads at several points simultaneously and with identical stroke. This is achieved by rigidly coupling all individual screw jacks mechanically to a single central drive motor. As long as the shafts are turning, all gearboxes are forced to move in exact synchronism. The reliability of such a system depends largely on careful design and precise assembly of the connecting elements.

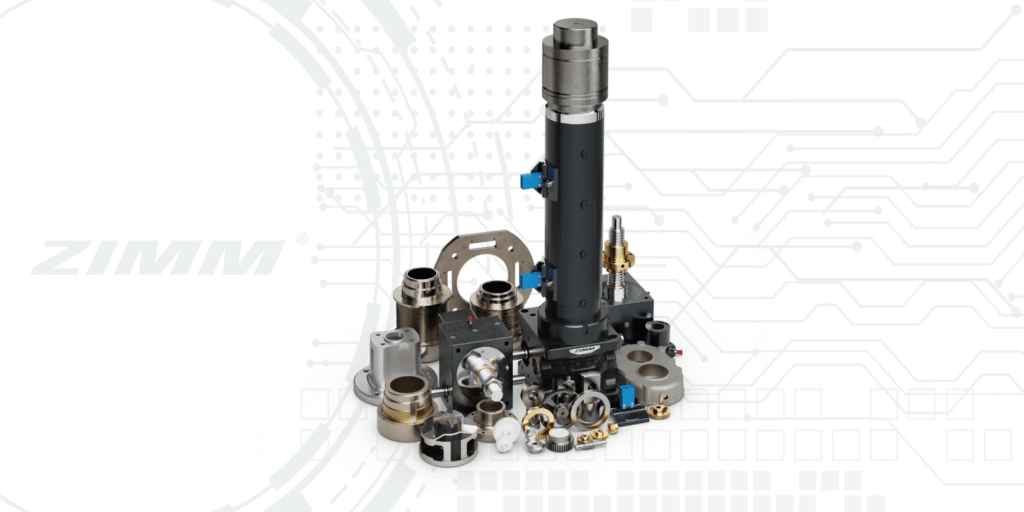

The components for mechanical synchronisation

A typical mechanically synchronised system consists of the following key components:

- Central drive motor: It provides the total power for the system and drives all screw jacks together.

- Screw jacks: The number (e.g. two, four or more) is determined by the load support points. Suitable sizes and screw types (TR/KGT, S or R version) can be combined via the ZIMM modular system.

- Bevel gearboxes: Bevel gearboxes (e.g. KSZ / KST series) are used to deflect the rotary motion of the horizontal connecting shafts by 90° onto the vertical input shafts of the screw jacks and to transmit high torques in a compact form.

- Connecting shafts: Connecting shafts (e.g. VWZ) transmit torque from the motor to the bevel gearboxes and between the individual screw jacks. Their sizing must be based on the torque to be transmitted and the critical speed; split-shell couplings allow simple radial installation.

- Couplings: Couplings (e.g. KUZ standard couplings) connect the shaft ends to each other and to the gearbox inputs. They compensate minor misalignments, damp shocks and can serve as safety or disconnect elements.

- Pedestal bearings: For long connecting shafts, additional pedestal bearings (e.g. STL) are used to support the shaft and prevent deflection or vibration at higher speeds. The installation height must be matched precisely to the other components.

Principles of system design

For robust and long-lasting synchronisation, the following principles should be observed in the design:

- Symmetrical load distribution: The motor should ideally be positioned so that torques and loads on the connecting elements are distributed as evenly as possible. A central power input in the middle of a long shaft line is often more favourable than feeding in from just one end.

- Minimum number of components: Every additional component (gearbox, shaft, bearing) introduces small efficiency losses and additional backlash. A layout that is as direct and simple as possible with short load paths increases efficiency, stiffness and service life of the system.

- Precise alignment: This is one of the most critical points. All screw jacks, bevel gearboxes, connecting shafts and pedestal bearings must be mounted exactly at the same height and in precise alignment. Even small misalignments lead to stresses in the system, generate radial forces on shafts and bearings and cause increased wear up to premature failure.

By consistently adhering to these principles, a mechanically synchronised lifting system is created that offers high precision, robustness and reliability – and all this without complex electronics, based solely on the mechanical ZIMM modular system.