Your basket is currently empty!

Ball screw drive vs. trapezoidal screw drive: What is the right choice for my application?

Is there a topic missing?

Despite our comprehensive wiki, you haven’t found the information you’re looking for? Then don’t hesitate to contact us directly.

Our team will be happy to help you personally – whether it’s specific applications, custom-made products or missing content. Together we will find the right solution.

Author:

Last modified:

A fundamental engineering decision that determines the performance, safety and cost of your drive.

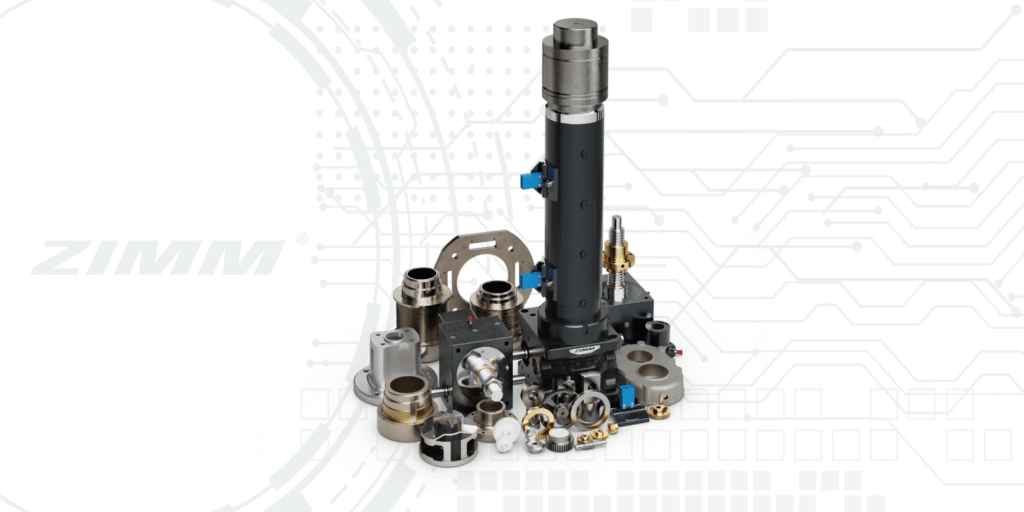

The choice between a ball screw drive (KGT) and a trapezoidal screw drive (TR) is one of the key decisions when designing linear axes, screw jacks and actuators. It is not about what is “better” in absolute terms, but about the optimum fit for the task – for example in terms of speed, precision, load-holding capability and budget. KGT stands for highest performance and efficiency (rolling friction), TR for robust simplicity and self-locking (sliding friction).

Physical difference and its consequences

- TR (sliding friction): The screw and nut slide against each other – simple, robust, cost-effective, with self-locking at small lead angles.

- KGT (rolling friction): Balls roll in raceways between screw and nut – very high efficiency, high dynamics and low heat generation, no self-locking → a brake is required for safe load-holding.

Decision matrix: Ball screw drive (KGT) vs. trapezoidal screw drive (TR)

| Criterion | Ball screw drive (KGT) | Trapezoidal screw drive (TR) |

| Operating principle | Rolling friction (balls roll in raceways) | Sliding friction (flanks slide directly) |

| Efficiency | Very high, energy-efficient | Lower, more power lost as heat |

| Maximum speed | Very high, dynamic traversing movements | Limited by heat generation |

| Duty cycle (ED) | Significantly higher – depending on design, up to 4× compared with TR | Limited, typically up to max. 20% for ZIMM TR |

| Precision / backlash | Backlash-free design possible by preloading, high stiffness | Play as standard, low-backlash versions possible |

| Self-locking | No → a brake is required for load-holding | Yes (at small lead angles, static/dynamic) |

| Service life (dynamic) | Very high, well predictable | Lower, more strongly dependent on wear |

| Breakaway torque | Low (low friction) | Higher (breakaway torque) |

| Robustness with respect to ambient conditions | More sensitive to contamination → sealing/lubrication must be considered | Very robust and insensitive |

| Cost | Higher (components & preload) | Lower |

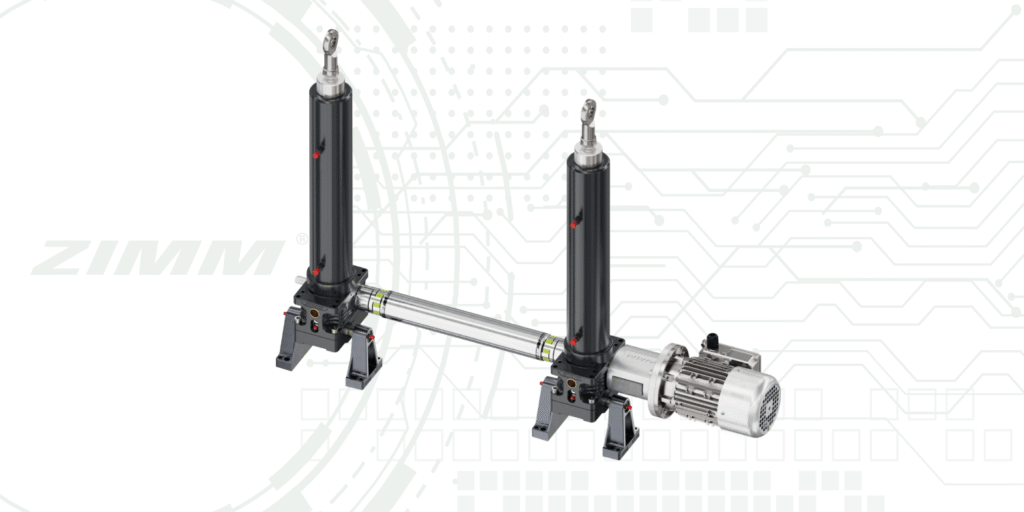

| Typische Anwendungen | CNC axes, automation, dynamic positioning, high duty cycles | Manual/occasional adjustments, format changes, static holding tasks, harsh environments |

| Practice: classification in the ZIMM modular system | KGT in ZIMM screw jacks/applications: For high dynamics, precision and duty cycle (e.g. ZE/ZE-H with KGT options). | TR in ZIMM screw jacks/actuators: When self-locking, cost-efficiency and robustness are the main focus (typically up to 20% duty cycle for TR at ZIMM). |

Conclusion: How to choose correctly

- Choose KGT when high speeds, continuous operation (high duty cycle), highest positioning accuracy and maximum energy efficiency are required. (Plan for a brake for load-holding.)

- Choose TR when self-locking is a safety feature, movements are infrequent/slow and budget as well as robustness are the main focus (e.g. format adjustments, manual adjustments).