Your basket is currently empty!

Increased efficiency and safety through automation

Author:

Published:

A use case from Knauf Ceiling Solutions and ZIMM

Discover the world of Knauf Ceiling Solutions, a premium ceiling brand that combines creativity, performance and collaboration at the highest level. As an integral part of the Knauf Group, which traces its roots back to the early 1920s, we have grown from humble beginnings in gypsum production by brothers Alfons and Karl Knauf to become an international market leader in building materials. With the merger of Knauf AMF and Armstrong Ceiling Solutions in 2019, we combine the expertise and tradition of two world-renowned brands under Knauf Ceiling Solutions. Headquartered in Munich, Germany, and supported by a global team of experts, we develop and produce innovative and high-quality ceiling and wall system solutions for various market segments.

Our advantage? No limits! We offer an incredibly versatile portfolio of ceiling, wall and suspension system solutions as well as professional support for your projects. Our mission: to beautify and protect the spaces where you live, work, heal and grow. Our 1,500 dedicated specialists around the world have the knowledge to respond to local challenges. With a wide range of materials, designs and colors as well as nine state-of-the-art production facilities at six locations in Europe and Asia, we guarantee on-time deliveries through our extensive global network for production, logistics and distribution. We are particularly proud of our site in Ferndorf, Austria, where we produce around 2 million square meters of wood wool panels every year. These magnesite-bonded HERADESIGN® panels offer outstanding acoustic and ecological properties.

The challenge: Modernizing a production line dating back to 1924

A milestone was recently reached: the modernization of the production lines by automating the tensioning of the 34-metre long double steel belt. This not only increases safety and efficiency, but also underlines Knauf Ceiling Solutions’ commitment to innovative solutions. The existing mechanical manual clamping required regular manual adjustments by employees. Given the extreme temperatures of up to 240°C, this task was not only inefficient, but also posed a significant safety risk. The solution was to fully automate the belt tensioning – a project that required the utmost precision, as uncontrolled tension regulation could lead to the steel belt breaking.

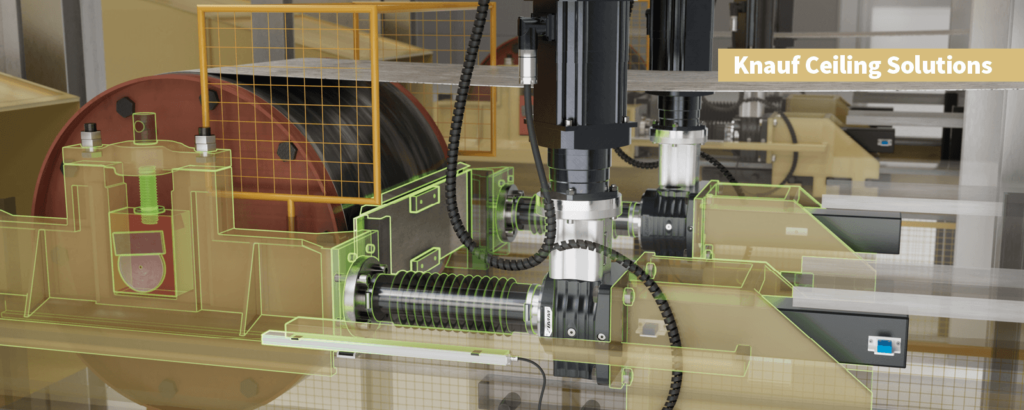

The solution: Automation with ZIMM screw jacks

A high-precision automation system was developed in close cooperation with ZIMM, Europe’s leading manufacturer of screw jacks. Two powerful ZE 250 screw jacks, each with a maximum force of 20 tons, were integrated into the system. The gearboxes regulate the belt tension in real time using pressure cells and ensure precise synchronization to keep the steel belt continuously in position.

A special feature of the solution is the control system developed in-house by Knauf Ceiling Solutions, which enables production staff to monitor and adjust the system at any time. This has not only significantly improved safety, but also optimized production output.