Your basket is currently empty!

Electromechanical actuators: Enhancing efficiency and precision in industrial applications

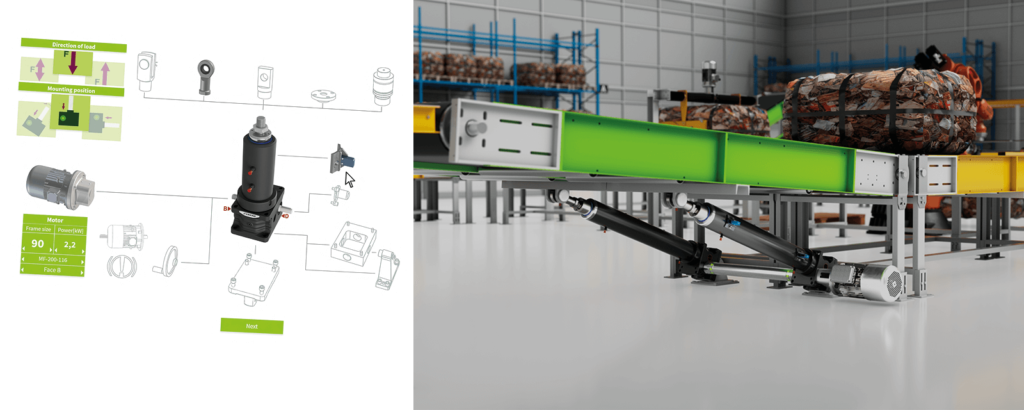

Optimized, fast, and simplified configuration: Electromechanical actuators now available in the product configurator

The demands of modern industrial plants are increasing: precise positioning, energy-efficient movements, and accurate control are becoming essential across more industries. Our advanced CAD product configurator enables simple and fast planning of electromechanical actuators for a wide range of industrial applications. This powerful tool helps improve efficiency and reduces design time by providing tailored solutions for every industrial need.

Features of the configurator:

- Four sizes and customizable accessories for maximum flexibility

- Real-time 3D and 2D preview for quick and reliable decisions

- Modular system for seamless integration into existing plants

- Advanced technical support to ensure optimal component selection

- Option to download CAD models for easy implementation

Why choose electromechanics over hydraulics?

- Energy Efficiency: No need for constant pressure generation – energy is consumed only when required, significantly reducing overall consumption.

- Cost Reduction: Eliminating oil changes and production downtimes lowers maintenance and operating costs.

- Operational Safety: Self-locking actuators prevent uncontrolled movements; additional monitoring systems enable safe, scheduled maintenance.

- Simple Integration: Compact design allows for flexible applications and easy retrofitting into existing plants.

- Environmental Friendliness: No use of hydraulic oils – reducing pollution risks and ensuring eco-friendly disposal.

Practical example: Increased efficiency with electromechanical actuators

An example from the recycling industry highlights the successful use of electromechanical actuators: They enable precise control of plant components, optimize sorting processes, and reduce energy consumption. Similar advantages can be observed in other industries:

- Logistics: Automated storage and transport technology with precise load movement improves the efficiency of the entire supply chain.

- Automotive Industry: Lifting and positioning systems in production lines ensure consistent quality and reduce assembly errors.

- Mechanical Engineering: High-precision control of machine components optimizes production processes and reduces maintenance costs.

- Food Industry: Accurate control of packaging lines enhances product quality and food safety.

Maximum flexibility through a modular system

In addition to actuators, we offer all necessary accessories – connecting shafts, couplings, motor flanges, and motors – tailored to your specific requirements. The modular system allows for future upgrades and adjustments, ensuring sustainable investments.

Electromechanical actuators are suitable for plants of any size, making them a strategic choice for growing companies. Their versatility enables tailored solutions for new challenges and easy integration into existing processes.

Conclusion: Switch to electromechanics now

Companies seeking to modernize their industrial processes benefit from electromechanical solutions through:

- More precise adjustments and positioning for improved product quality

- Lower energy and maintenance costs for faster return on investment

- Increased safety and reliable integration to minimize unexpected downtimes

- Greater sustainability by eliminating harmful hydraulic oils