Your basket is currently empty!

What is the duty cycle (ED) and how does it affect the design?

Is there a topic missing?

Despite our comprehensive wiki, you haven’t found the information you’re looking for? Then don’t hesitate to contact us directly.

Our team will be happy to help you personally – whether it’s specific applications, custom-made products or missing content. Together we will find the right solution.

Author:

Last modified:

The decisive parameter for the thermal load capacity and service life of your drive.

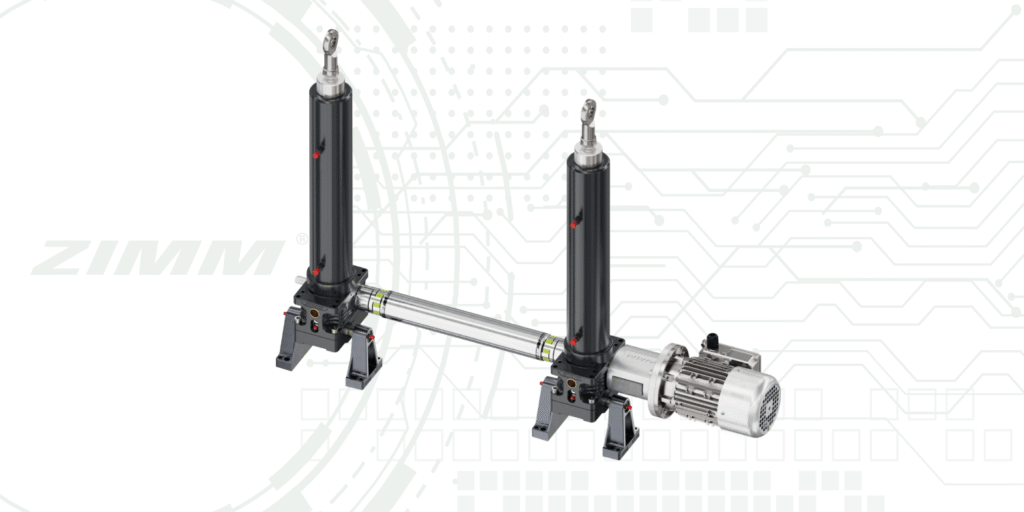

The duty cycle (ED) describes the ratio of operating time to pause time within a defined cycle (typically 1 h) and is given in %. Example: 20% ED per hour means a maximum of 12 min operation and 48 min pause per hour so that the gearbox remains within the permissible thermal range. At ZIMM, trapezoidal screw drives are typically intended for applications up to approx. 20% ED; with a ball screw drive, significantly higher ED values are possible (ZIMM: up to 4× compared with TR, depending on the design).

The thermal background

ED is limited by heat generation. Losses arise mainly

- in the worm gearbox (friction between worm and worm wheel) and

- in the screw drive – significantly more in TR due to sliding friction than in KGT with rolling friction.

The heat must be dissipated to the environment via the housing/lubricant; otherwise the operating temperature rises to an impermissible level. ZIMM product data and diagrams for the “duty cycle thermal limit” show the permissible ED as a function of load and speed (guide values at 20 °C ambient). Individual data sheets also specify temperature limits for the gearbox (e.g. max. 60 °C, higher on request).

Influencing factors on the duty cycle

The permissible ED is not a fixed value, but results from the power loss (heat) generated in operation:

- Load: Higher load ⇒ higher drive torque ⇒ more friction ⇒ ED decreases. (See ED curves vs. kN.)

- Speed/rotational speed: More friction cycles per unit of time ⇒ ED decreases. (ED curves vs. rpm.)

- Gearbox type: TR, due to sliding friction, usually ED ≈ up to 20%; KGT generates less heat ⇒ significantly higher / almost continuous-duty ED possible (application-dependent).

- Ambient conditions & cooling: Higher ambient temperature or poor heat dissipation reduce the permissible ED. (ZIMM curves are based on ~20 °C and correct lubrication.)

Relevance for the design

When selecting a screw jack, ED is one of the most important input parameters:

- Stay below rated load: If the rated power is not fully utilised, less power loss is generated – effectively resulting in a higher ED in real operation. (The curves provide guidance for load/speed combinations.)

- Select a “thermally larger” size: For high cycle rates/long strokes, it is often advisable to choose a larger size or a KGT variant in order to increase heat dissipation and ED reserves. ZIMM explicitly points out high performance and long ED for ZE/ZE-H.

- Observe limit values: Comply with ED diagrams (duty-cycle curves) and temperature specifications for the specific series; if necessary, adapt cooling measures and/or operating strategy (cycles/pauses).

Short conclusion: ED controls the thermal behaviour. Anyone who carefully balances ED, load and speed (and uses a KGT where appropriate) avoids overheating, protects lubricant and bearings, and maximises the service life of the entire drive system.

Category:

Questions and answers about our products