Your basket is currently empty!

How do I choose the right screw jack? (Checklist)

Is there a topic missing?

Despite our comprehensive wiki, you haven’t found the information you’re looking for? Then don’t hesitate to contact us directly.

Our team will be happy to help you personally – whether it’s specific applications, custom-made products or missing content. Together we will find the right solution.

Author:

Last modified:

A systematic process that ensures all critical parameters of your application are taken into account.

Selecting the right screw jack is a multi-stage engineering process in which parameters interact with each other (for example, higher speed reduces the buckling safety margin). This guide leads you through all steps in a structured way – from load to the safety concept – and serves as a working document for design, comparison and documentation.

The selection process: Step by step to the optimum gearbox

Note on use: Enter your application data in the table and tick off each check/decision. For borderline cases, design conservatively (safety factors) and also evaluate system effects (shafts, couplings, guides, bearings).

| Step | Parameter | Check / decision |

| Load & force | Maximum load (kN) static/dynamic | Rated load > maximum load; safety factor ≥ +30% static, ≥ +10% dynamic |

| Direction of load compression/tension/both | For compression: Buckling verification required | |

| Side loads | Avoid; provide external guides | |

| Motion | Speed (mm/s) | Determines speed/screw pitch; n_operating ≤ 0.8·n_crit |

| Stroke (mm) | Long stroke ↑ → check buckling risk/n_crit; if necessary, larger screw/size | |

| Operation | Duty cycle (ED %/h) | Check thermal behaviour; > 20–30% → ball screw / larger size / cooling strategy |

| Positioning accuracy (mm) | Standard vs. low-backlash (TR) / preloaded (KGT) | |

| System & type | Screw type TR/KGT | TR = self-locking; KGT = dynamics/efficiency, brake for holding |

| Version basic/travelling nut | Select according to installation space/load connection | |

| Mounting | Kubisches Gehäuse, Konsolen/Flansche passend zur Konstruktion ausSelect suitable cubic housing, brackets/flanges | |

| Environment | Temperature/humidity/contamination/chemicals | Material, seals, lubricant; bellows if necessary |

| Safety | Safety factors | Document; be conservative for lifting people/loads |

| Buckling load | Euler/Tetmajer, target SF 3–6 | |

| Critical speed | n_operating ≤ 80% n_crit | |

| Holding/self-locking | TR may be (statically/dynamically) self-locking; KGT with motor brake | |

| Functional safety | Limit switches/encoder, overload/crush protection, emergency stop |

ZIMM practical notes (for the concrete selection)

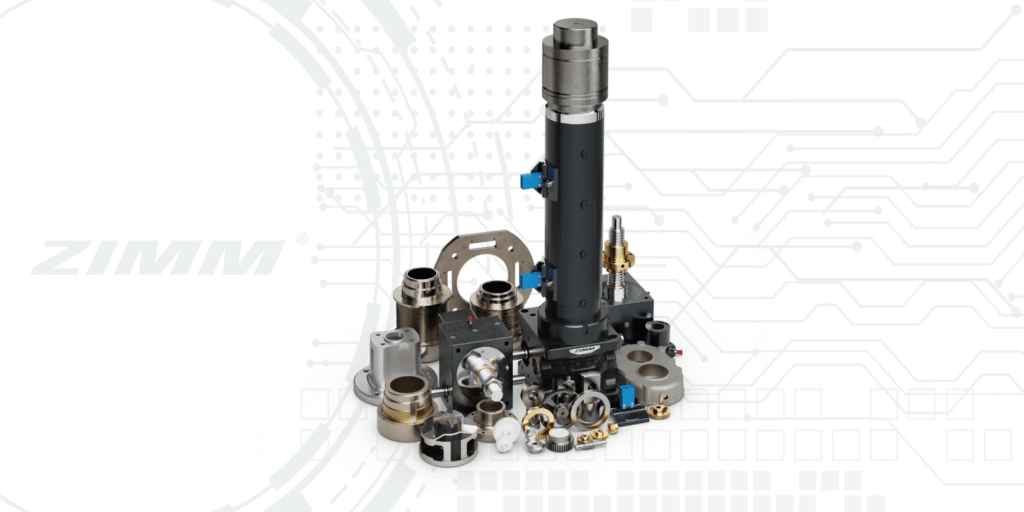

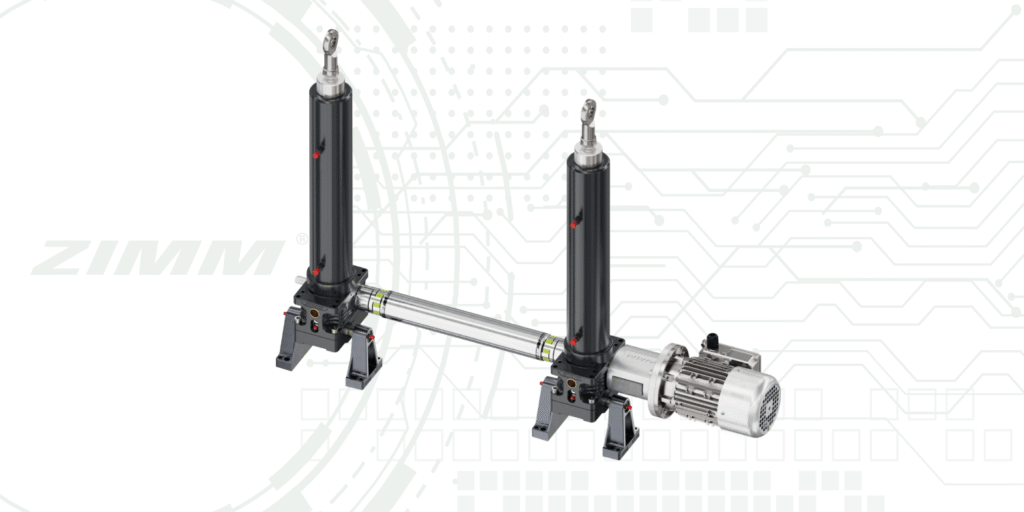

- Series selection: ZE/ZE-H/GSZ (screw jacks) depending on load/stroke/ED; ZA (actuators) for compact linear drives; KSZ-H/KST for 90° deflection and power distribution in multi-point systems.

- Play & stiffness: TR with low-backlash/adjustable nut = robust & self-locking; KGT with preload = backlash-free & stiff (plan brake for holding).

- Thermal behaviour (ED): High ED → larger size, ball screw, optimised lubrication, if necessary adapted operating cycles/cooling.

- System integration: Suitable connecting shafts/couplings/brackets from the ZIMM modular system for precise alignment and smooth running.

- Documentation: Load assumptions, calculations (buckling, n_crit), ED verification, safety considerations, assembly/test records.

Short conclusion

Once load, speed, stroke, ED, environment and safety have been systematically checked, the final selection of gearbox, motor, transmission (bevel gearboxes, shafts, couplings) and accessories follows. This way you avoid incorrect designs and maximise service life and operational safety.

Category:

Questions and answers about our products